Have you ever wondered what wuld happen if you poured a strong acid onto a stainless steel block? Would the acid melt the steel? The answer is yes! Acid can, in fact, dissolve stainless steel.

When stainless steel comes in contact with an acid, a reaction occurs that produces hydrogen gas and ferrous ions. This reaction forms a protective layer of FeSO4 on the metal surface. The lower the pH level, the more strongly acidic the fluid. Stomach acid, for example, has a pH level of 1.0-2.0 and is capable of dissolving steel.

The fastest way to dissolve stainless steel electrochemically is by using H A 2 SO A 4 at elevated temperatures. By attaching the steel block as an anode to this solution, it will slowly begin to corrode and eventually dissolve into small particles. This process is known as “acid etching.”

Acid etching can be used for a variety of applications such as smoothing out rough edges on metal or creating intricate patterns or designs on metal surfaces. It is also used in industrial applications such as cleaning or removing rust from machinery parts and preparing surfaces for painting or coating processes.

While acid etching can be useful in many ways, it also poses certain risks due to its corrosive nature. It is important to always use safety equipment when working with acids and to ensure proper ventilation when working in enclosed spaces. Additionally, acids should never be ingested or come into contact with skin and eyes as they can cause serious burns and irritation if not treated quickly enough with water or other neutralizing agents such as baking soda or vinegar.

So there you have it – acid does indeed melt stainless steel! While this may seem like a hazardous process, it can be done safely with proper precautions and techniques in place to ensure your safety while using acids for various projects around your home or workplace.

The Reaction of Acid and Steel

When an acid reacts with steel, a salt and hydrogen gas are produced. The salt is formed due to the combination of the positive ions from the steel and the negative ions from the acid. Hydrogen gas is produced through a process known as reduction, where electrons are removed from the steel atoms and transferred to the acid molecules. This process causes the hydrogen atoms in the acid to become ionized, releasing them as gas molecules.

What is the Fastest Acid for Dissolving Steel?

The fastest way to dissolve steel is by using an electrochemical process with sulfuric acid (H2SO4) at elevated temperatures. In this process, the steel block is attached as the anode, and a direct current is passed through it in a solution of sulfuric acid. The electrical current causs an electrochemical reaction which breaks down the steel and dissolves it into its component ions. This process is much faster than traditional acid etching or chemical dissolution methods, and allows for precise control of the dissolution rate.

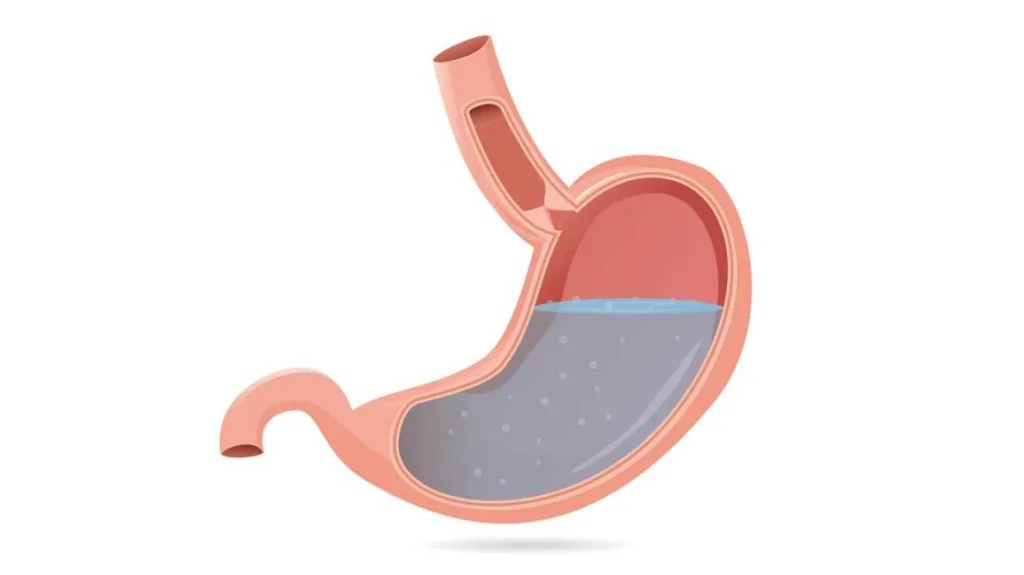

The Effects of Stomach Acid on Steel

No, stomach acid cannot melt steel. Despite its incredibly low pH level, the acidity of stomach acid is not strong enouh to corrode or dissolve steel. Steel is a very strong and durable metal that is not affected by gastric acid in the same way that it is affected by battery acid.

The Chemical Reaction Between Acid and Steel

Steel, an alloy of iron and carbon, reacts with concentrated sulfuric acid to form hydrogen gas and ferrous ions. This reaction is represented by the following equation:

Fe + H2SO4 –> FeSO4 + H2 (Reaction 1). The ferrous ions form a protective layer of FeSO4 on the steel surface, protecting it from furter corrosion. Although steel generally has good corrosion resistance, it can be corroded in many environments, including acidic ones. Therefore, when in contact with concentrated sulfuric acid, steel will react immediately and produce hydrogen gas and ferrous ions.

The Effects of Acid on Steel

Steel is generally resistant to acidic corrosion, but its exact level of resistance will depend on the type of steel, the concentration and type of acid, and environmental temperature. In general, stainless steel is more resistant to corrosive acids than other forms of steel. Normally, milder concentrations of common acids such as hydrochloric and nitric acid do not case significant damage to steel. However, higher concentrations or prolonged exposure can erode the protective oxide layer on the steel surface and lead to further corrosion. Additionally, certain types of acid such as sulfuric acid can be very damaging to steel even in lower concentrations. Therefore, it is important to ensure that the appropriate grade of steel is used in an application where acidic corrosion resistance is required.

The Effects of Acid on Steel

Yes, steel is affected by acid. Steel is a type of metal, and all metals are vulnerable to corrosion when exposed to acid. The acid reacts with the metal in the steel, leading to degradation of the material. Rust can form on the surface of the steel, weakening its structural integrity and making it more susceptible to further damage. To prevent acid corrosion, steel must be treated with protective coatings or alloys that are resistant to acid damage.

The Destruction of Steel

Steel is a durable metal, but it can be easily destroyed by exposure to certain elements. The most common cuse of steel deterioration is oxidation, or rusting, which occurs when iron in the steel reacts with oxygen and moisture in the air. Steel can also be damaged by contact with other substances such as acids, alkalis, salts, and some cleaning chemicals. Exposure to extreme temperatures can also weaken steel and cause it to fail structurally over time. In addition, mechanical damage from overly aggressive cleaning methods or harsh scrubbing agents can damage the protective layers on steel surfaces and lead to corrosion.

The Effects of Hydrochloric Acid on Steel

Hydrochloric acid is a powerful corrosive agent that can cause significant damage to steel. When exposed to hydrochloric acid, the protective passivation film on the surface of the steel will be destroyed, leading to comprehensive corrosion of the material. This can result in pitting corrosion and stress corrosion cracking of the steel. Additionally, hydrochloric acid can react with cetain alloys in steel to create hazardous fumes that are harmful to human health. Prolonged exposure or contact with hydrochloric acid can cause serious damage, so it is important to take proper safety precautions when handling this material.

Metals That Cannot Be Dissolved by Acid

Metal that cannot be dissolved by acid are metals found at the bottom of the metal reactivity series, such as gold, platinum, and palladium. These metals are typically very unreactive and thus do not react with acids to form soluble compounds. Some oher examples of non-reactive metals include iron, nickel, and lead. While these metals can sometimes be corroded or tarnished by acid, they will not dissolve in it.

What is the Strongest Acid in the World?

The strongest acid in the world is fluoroantimonic acid, which is a superacid mixture of antimony pentafluoride and hydrofluoric acid. This mixture produces an extremely strong proton donor with a Hammett acidity function (H0) of -31.3, which is an indication of its exceptional strength. Fluoroantimonic acid is approximately 10^16 times stronger than 100% sulfuric acid, and it has no known equal when it comes to its sheer strength. The acid can corrode glass or metal and even dissolve diamond, making it a highly hazardous substance that must be handled with extreme caution.

Dissolution Time of Metal in Stomach Acid

It depends on the type of metal, as well as the concentration of the stomach acid. Generally speaking, metals such as aluminum and iron can take anywhere from a few minutes to sevral hours to dissolve in stomach acid. However, certain metals such as chromium and nickel tend to be more resistant and can take up to 24 hours or longer to dissolve in stomach acid.

Can Stomach Acid Dissolve a Razor Blade?

No, your stomach acid cannot melt a razor blade. Stomach acid, or hydrochloric acid, has a pH of 1-3 whih is very acidic but not strong enough to break down metal. Razor blades are made from stainless steel and can withstand extremely high temperatures. Even if exposed to the highest levels of stomach acid, a razor blade would remain intact.

The Effects of Sulfuric Acid on Steel

Sulfuric acid is highly corrosive to carbon steel and can caue a variety of forms of corrosion, depending on the exposure conditions. Under stagnant or low-flow conditions, sulfuric acid causes general thinning or pitting of the steel, known as generalized corrosion. In addition, hydrogen grooving, blistering, and preferential weld attack may occur in certain environments. As a result, it is important to establish protective measures when working with this material.

The Power of Acid: What Can It Melt?

The acid known as “magic acid” is a highly corrosive and powerful superacid composed of antimony pentafluoride (SbF5) and fluorosulfonic acid (FSO3H). It has earned its name due to its incredible ability to dissolve amost any material, even those that are considered inert hydrocarbons. Its incredible power to shatter seemingly impenetrable substances makes it a valuable tool in chemistry laboratories worldwide.

The Acid That Can Melt Iron

Iron cannt be melted by acid; however, hydrochloric acid can dissolve iron in a reaction known as corrosion. When hydrochloric acid is applied to iron, the hydrogen ions from the acid react with the iron atoms, forming iron chloride and hydrogen gas. The more concentrated the hydrochloric acid solution is, the faster it will dissolve the iron.

Conclusion

In conclusion, acid can be used to melt steel in a controlled environment. The most common method is to use sulfuric acid in a highly concentrated form and at an elevated temperature to allow for electrochemical dissolution of the steel. This reaction produces hydrogen gas and ferrous ions which form a protective layer of FeSO4 on the surface of the steel. However, it sould be noted that this process is not suitable for all types of steel and should only be attempted by those who are experienced in handling corrosive materials.