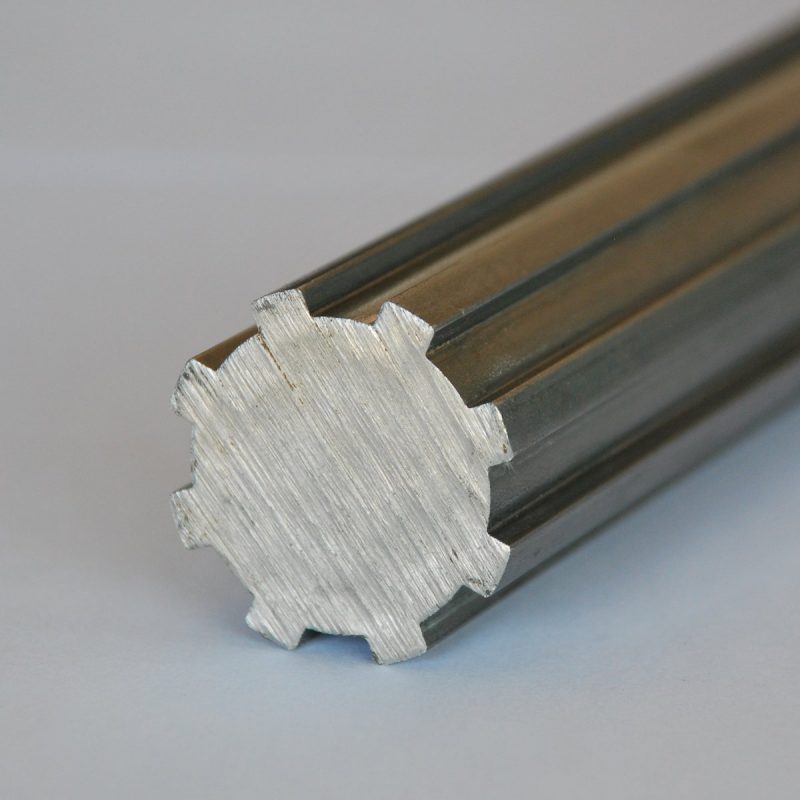

Splined shafts are an integral part of many mechanical systems, particularly those that require the transmission of torque between rotating components. These shafts are characterized by the presence of deep grooves, or splines, cut along their entire length. These splines create jutting keys that fit into corresponding grooves or teeth on other components, such as bearings, gears, or bushings. This design allows for the efficient transfer of rotational motion and torque.

The primary purpose of splined shafts is to provide a strong and secure connection between two rotating components. By using the splines to interlock with the teeth or grooves on the mating component, the shaft can transmit torque without slipping or losing efficiency. This is particularly important in applications where high torque loads are involved, as splined connections can provide a significant increase in strength compared to other types of couplings.

There are various types of splines used in industrial applications, each with its own specific design and purpose. Some common types include involute splines, serrated splines, and straight-sided splines. These different spline designs allow for variations in load capacity, alignment accuracy, and ease of assembly.

In addition to their use in transmitting torque, splined shafts also provide the added benefit of allowing for limited linear motion. This is because the splines restrict movement in the axial direction, while still allowing for free rotation. This feature is particularly useful in applications where both rotational and linear motion are required, such as in automotive steering systems or power transmission systems.

To ensure proper functioning and longevity of splined shafts, it is important to maintain proper lubrication between the mating components. This helps to reduce friction and wear, ensuring smooth operation and preventing premature failure.

Splined shafts play a crucial role in many mechanical systems, allowing for the efficient transmission of torque and limited linear motion. Their unique design and interlocking splines provide a strong and secure connection between rotating components, making them an essential component in various industrial applications.

What Is A Splined Shaft?

A splined shaft is a type of shaft that is commonly used in mechanical systems. It is characterized by deep grooves, called splines, which are cut along the entire length of the outer material. These splines create jutting keys that serve as a form of connection for various components in the system.

The purpose of these splines is to provide a secure and precise fit with other parts of the machinery. The splined shaft is designed to mate with paired bearings, bores, gears, or bushings that have corresponding grooves or slots. This allows for a strong and reliable connection between the shaft and the other components.

The use of splines in a shaft offers several advantages. Firstly, it provides a large surface area for transmitting torque, which enhances the power and efficiency of the system. The splines also help to distribute the load evenly, reducing stress concentration on specific areas of the shaft. This promotes durability and longevity of the components.

Furthermore, the splined shaft allows for easy assembly and disassembly of the system. The mating parts can be quickly and securely connected or disconnected, facilitating maintenance and repair processes.

A splined shaft is a specialized type of shaft with deep grooves or splines that serve as keys for connecting with other components in a mechanical system. Its design provides a strong and precise connection, enhances torque transmission, distributes load evenly, and allows for easy assembly and disassembly.

What Is Spline Used For?

Splines are utilized in a wide range of industrial applications for the purpose of transmitting torque between two components. These components can be shafts, gears, or any other rotating elements.

Here are some specific uses of splines:

1. Power transmission: Splines are commonly employed in mechanical power transmission systems to transfer torque from a driving component to a driven component. By interlocking the grooves or teeth of the spline on the shaft with the corresponding grooves or teeth on the other component, rotational motion can be transmitted efficiently.

2. Automotive industry: Splines are extensively used in the automotive industry for various applications. They are used in the transmission system to connect the gearbox with the drive shaft, allowing the engine power to be transferred to the wheels. Splines are also found in steering systems, where they connect the steering column with the steering wheel, enabling the driver to control the direction of the vehicle.

3. Aerospace industry: In aircraft and spacecraft, splines find applications in the propulsion system, specifically in connecting the engine to the propeller or turbine. They are also utilized in the control surfaces, such as the ailerons and elevators, to transmit the pilot’s input into the desired movement of the aircraft.

4. Industrial machinery: Splines are used in various types of industrial machinery, such as pumps, compressors, and generators. They play a crucial role in transmitting power and ensuring the synchronized operation of different components within the machinery.

5. Robotics: In robotic applications, splines are utilized in the joints of robotic arms to enable precise movement and control. They allow the robot to perform complex tasks by transmitting torque and rotational motion between the different segments of the arm.

6. Construction equipment: Splines are employed in construction equipment, such as excavators and bulldozers, for transmitting power from the engine to the various moving parts. They ensure efficient operation and reliable performance of these heavy-duty machines.

Splines are used in a diverse range of industries and applications to transmit torque and enable both linear and rotational motion between components. Their versatility and reliability make them an essential element in many mechanical systems.

What Is The Definition Of A Spline?

A spline is a slender strip made of wood or metal that is commonly used in the construction industry. It serves as a reinforcement or support in various building structures. Splines are often used to strengthen joints or connections between two parts.

In the mechanical field, a spline can also refer to a key that is fixed to one of two connected mechanical parts. This key fits into a keyway in the other part, creating a secure and precise connection. The keyway is a groove or channel specifically designed to accommodate the spline key.

To summarize, a spline is a thin strip used in construction to reinforce or support structures, or a key and keyway mechanism used in mechanical connections.

What Is A Splined Coupling?

A splined coupling is a mechanical device that connects two rotating shafts and allows them to transmit torque. It consists of two main components: a shaft with external teeth and a hub with internal teeth. The teeth on the shaft and hub are designed to engage with each other, creating a secure connection.

Here are some key points to understand about splined couplings:

1. Purpose: The main purpose of a splined coupling is to transfer torque from one shaft to another. It allows for the efficient transmission of power between rotating components.

2. Teeth Design: The teeth on the shaft and hub are precisely machined to ensure a proper fit and engagement. They may be straight-sided or involute in shape, depending on the specific application requirements.

3. Load Distribution: The teeth on the coupling enable the load to be distributed evenly across the engagement area. This helps to minimize stress concentrations and prevents excessive wear and damage to the coupling.

4. Alignment: Proper alignment between the shaft and hub is crucial for effective torque transmission. Misalignment can result in increased wear, vibration, and reduced efficiency. Therefore, it is important to ensure accurate alignment during installation.

5. Torque Capacity: The torque capacity of a splined coupling depends on various factors such as the number of teeth, tooth profile, material strength, and lubrication. It is essential to select a coupling with sufficient torque capacity to handle the anticipated loads.

6. Types of Splined Couplings: There are different types of splined couplings available, including straight-sided, involute, and helical splines. The choice of coupling type depends on the specific application requirements and the level of torque transmission needed.

7. Applications: Splined couplings are commonly used in various industries, including automotive, aerospace, machinery, and power transmission systems. They are used in applications such as drive shafts, gearboxes, pumps, compressors, and turbines.

A splined coupling is a mechanical component used to connect and transmit torque between two rotating shafts. It consists of a shaft with external teeth and a hub with internal teeth, which engage with each other to transfer power efficiently. Splined couplings are crucial for ensuring smooth and reliable operation in various industrial applications.

Conclusion

A splined shaft is a specialized mechanical component used in various industrial applications. It is characterized by the presence of deep grooves, or splines, cut along its length, which create jutting keys. These keys fit into paired bearings, bores, gears, or bushings that are designed to mate with the shaft splines. Splined shafts are primarily used when both linear and rotational motion is desired, allowing for the transmission of torque between two rotating shafts.

Furthermore, spline couplings play a crucial role in connecting and transmitting torque between two rotating shafts. Consisting of a shaft with external teeth and a hub with internal teeth, the load is transferred from the shaft to the hub (or vice-versa) through engaging teeth. This ensures a secure and efficient transmission of power.

Splined shafts and spline couplings are integral components in many industries, including automotive, construction, and machinery. Their design and functionality provide precise and reliable torque transmission, allowing for smooth and efficient operation of various mechanical systems.