When it comes to subflooring, Coosa Board stands head and shoulders above traditional plywood. This innovative material offers a wide range of advantages that make it the top choice for various applications. From its lightweight nature to its exceptional durability, Coosa Board is a game-changer in the construction industry.

One of the most significant advantages of Coosa Board is its weight. Compared to plywood, Coosa panels are 40-60% lighter, depending on the density ordered. This weight reduction brings numerous benefits, including easier handling and installation. With Coosa Board, you can say goodbye to the back-breaking labor associated with maneuvering heavy plywood sheets.

But weight is not the only factor that sets Coosa Board apart. Unlike plywood, Coosa panels are essentially waterproof. This means they will never rot or go soft, even when exposed to moisture. Plywood, on the other hand, is notorious for absorbing water, leading to decay and weakening of the material over time. With Coosa Board, you can rest assured that your subfloor will remain strong and unaffected by water damage.

Furthermore, Coosa Board is impervious to mold, bugs, and varmints. Plywood can be a haven for these unwanted pests, causing structural issues and health hazards. Coosa panels, with their foam core construction, eliminate this concern entirely. You can say goodbye to costly pest control measures and enjoy a worry-free subflooring solution.

Another advantage of Coosa Board is its ease of use. Despite its lightweight nature, Coosa panels are just as strong and easy to work with as plywood. Whether you’re cutting, drilling, or shaping the material, Coosa Board offers excellent workability. This versatility makes it suitable for a wide range of applications beyond subflooring, including boat transoms and structural components.

While Coosa panels do not require encapsulation in fiberglass and resin to prevent water absorption, many choose to reinforce the material with this additional layer. Glassing the panel not only adds stiffness and strength but also provides an extra layer of protection against moisture. This optional step can further enhance the durability and longevity of your Coosa subfloor.

Coosa Board is undoubtedly the superior choice for subflooring and other structural applications. Its lightweight nature, waterproof properties, resistance to mold and pests, and ease of use make it the ultimate subfloor material. Whether you’re building a new home, renovating an existing one, or embarking on a boat construction project, Coosa Board is the go-to solution for a reliable, long-lasting subfloor that will stand the test of time.

In closing, the benefits of Coosa Board speak for themselves. Its lighter weight, waterproof nature, and resistance to mold and pests make it an exceptional alternative to plywood. With Coosa Board, you can enjoy peace of mind knowing that your subfloor will remain strong, durable, and unaffected by moisture. Make the switch to Coosa Board and experience the future of subflooring today.

Is Coosa Board As Strong As Plywood?

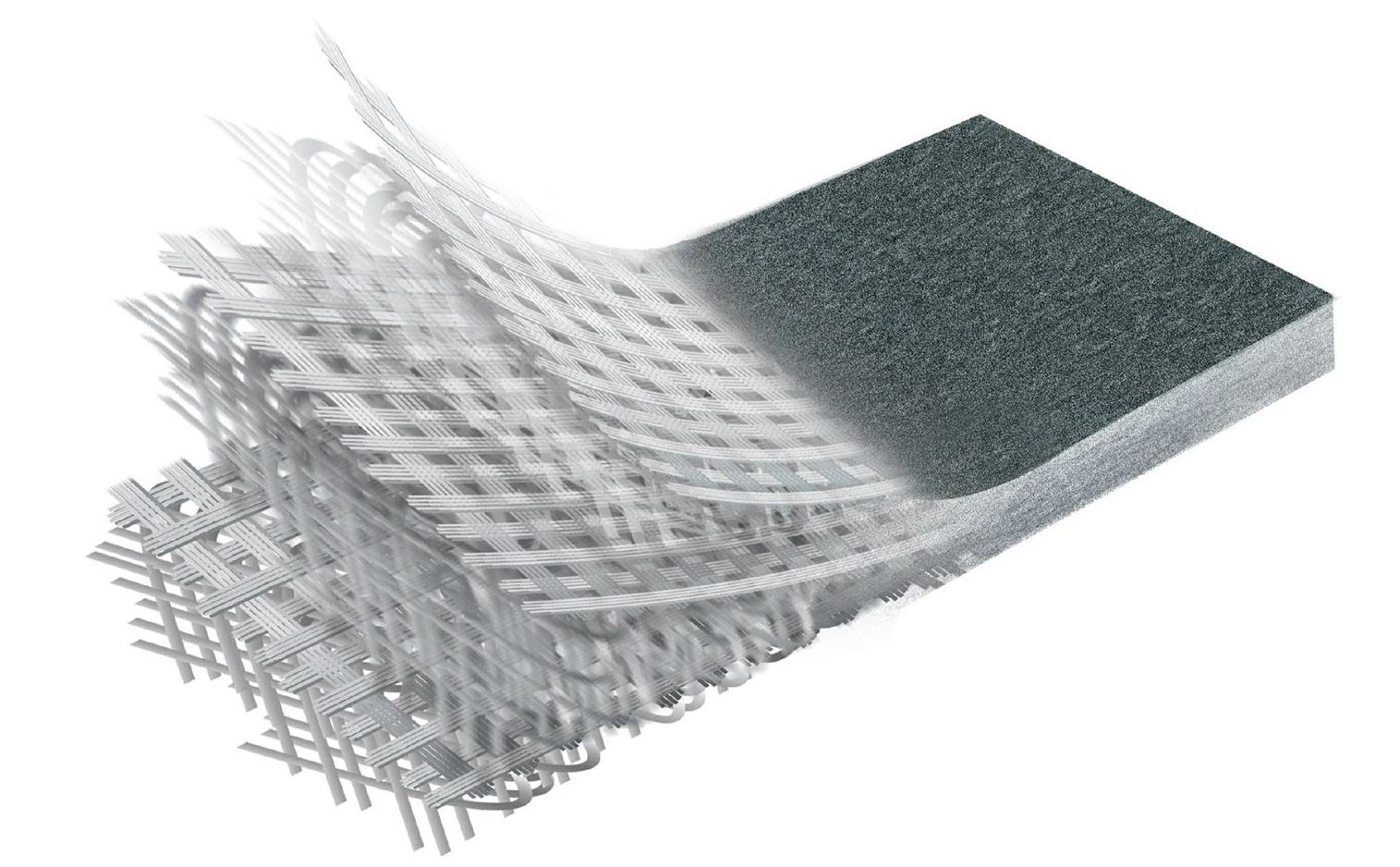

Coosa Board is as strong as plywood. In fact, it is just as strong and durable, if not stronger, than traditional plywood. Coosa Board is made from high-density polyurethane foam reinforced with fiberglass on both sides. This construction gives it excellent strength and rigidity, making it a reliable subfloor material.

The high-density polyurethane foam used in Coosa Board provides exceptional strength-to-weight ratio. It is lightweight, yet extremely strong, allowing it to withstand heavy loads without bending or warping. This makes it a suitable alternative to plywood for various applications, including subfloors.

In addition to its strength, Coosa Board is also resistant to water. Unlike plywood, which can absorb moisture and eventually rot or go soft, Coosa Board is essentially waterproof. This means it will not degrade or lose its strength when exposed to water or high humidity. It is also impervious to mold, bugs, and other pests, ensuring long-lasting durability.

Furthermore, Coosa Board is easy to work with. It can be cut, drilled, and shaped using standard woodworking tools, making installation hassle-free. Its lightweight nature also makes it easier to handle and transport compared to plywood.

Coosa Board is indeed as strong as plywood, if not stronger. Its high-density polyurethane foam construction provides exceptional strength and rigidity, while its waterproof and resistant properties make it a durable choice for subflooring.

Does Coosa Board Need To Be Sealed?

Coosa board, being a high-density foam composite panel, does not necessarily need to be sealed to prevent water absorption. Unlike plywood, which is prone to water damage and rot, Coosa board is inherently resistant to moisture. Its closed-cell structure makes it highly waterproof and does not allow water to penetrate or be absorbed by the material.

However, while sealing Coosa board is not a requirement, it is worth noting that adding a layer of fiberglass and resin can enhance the panel’s stiffness and strength. This process, known as glassing, involves encapsulating the Coosa board in a fiberglass cloth and applying layers of epoxy resin. The resin-soaked fiberglass cloth adheres to the surface, creating a protective barrier that adds structural integrity to the panel.

Glassing the Coosa board can be particularly beneficial in applications where additional strength and rigidity are desired, such as in boat construction, decking, or other marine-related projects. The fiberglass layer helps distribute stresses evenly across the panel, making it more resistant to bending or flexing.

While Coosa board does not require sealing to prevent water absorption, glassing the panel with fiberglass and resin can provide added stiffness and strength, making it a popular choice for marine applications.

Is Coosa Board Waterproof?

Coosa board is indeed waterproof. This foam core panel is designed to be highly resistant to water. Its composition and construction make it impervious to water absorption, preventing any rotting or water damage. The material used in Coosa board does not attract fungus or mold, ensuring its longevity and durability. This waterproof characteristic makes Coosa board an ideal choice for various applications where exposure to water is common, such as boat transoms, decks, and other marine uses. The water resistance of Coosa board also adds to its lightweight nature, as it doesn’t absorb water and become heavy over time. Coosa board’s waterproof properties make it a reliable and long-lasting option for structural applications in environments where moisture and water exposure are factors to consider.

Key features of Coosa board’s waterproof nature include:

– Lightweight: Coosa board is significantly lighter than plywood, making it easier to handle and transport.

– Rot-resistant: Unlike wood, Coosa board does not rot when exposed to water or moisture.

– Fungus-free: Coosa board does not attract fungus or mold, ensuring a clean and hygienic environment.

– Water resistance: The composition of Coosa board makes it highly resistant to water absorption, making it suitable for use in wet or damp conditions.

Coosa board’s waterproof properties make it a versatile and reliable choice for a range of applications that require a lightweight, durable, and water-resistant material.

Is Coosa Board Lighter Than Plywood?

Coosa boards are indeed lighter than plywood. In fact, they are 40-60% lighter than plywood, depending on the density ordered. This significant difference in weight can be attributed to the unique composition of Coosa panels. Unlike plywood, Coosa boards do not consist of layers of wood veneers. Instead, they are made from a high-density polyurethane foam core with layers of fiberglass reinforcement on both sides.

The absence of wood layers in Coosa panels contributes to their lightweight nature. Plywood, on the other hand, is made by gluing together multiple layers of wood veneers, which adds significant weight to the final product.

Not only are Coosa boards lighter, but they also offer another advantage over plywood. These panels do not absorb water to any significant degree. This means that when exposed to water, there is no significant weight gain in Coosa boards. This is a stark contrast to plywood, which tends to absorb water and becomes heavier when exposed to moisture.

By being significantly lighter and water-resistant, Coosa boards provide a superior alternative to plywood in various applications where weight reduction and water resistance are important factors.

Conclusion

Coosa Board is an exceptional subfloor material that surpasses plywood in several key aspects. Its lightweight nature, being 40-60% lighter than plywood, makes it easier to handle and transport. Additionally, Coosa Board is essentially waterproof, meaning it will never rot or go soft, making it highly durable and long-lasting.

One of the standout features of Coosa Board is its resistance to mold, bugs, and other varmints. Unlike plywood, it is impervious to these common issues, ensuring a clean and safe environment. This resistance to moisture and pests also makes Coosa Board an ideal choice for outdoor applications, such as boat transoms.

Another advantage of Coosa Board is its ease of workability. It maintains the same level of strength as plywood while being much lighter and more flexible. This flexibility allows for easier installation and customization to fit specific project requirements.

Furthermore, Coosa Board eliminates the need for encapsulation in fiberglass and resin, which is typically required for plywood to prevent water absorption. This not only saves time and effort but also reduces overall costs.

Coosa Board is a superior alternative to plywood, offering numerous benefits such as lightweight construction, water resistance, durability, and ease of use. Whether for marine, construction, or other structural applications, Coosa Board stands out as the best choice for a reliable and long-lasting subfloor material.