Headwall flashing is a vital component of any roofing system. It is used to ensure that water does not penetrate the junction between the roof and the vertical wall. The flashing helps to prevent leaks and water damage to the roof structure, as well as the interior of the building.

There are several diferent types of headwall flashing available, each designed for a specific application. The most common types of headwall flashing are L flashing, end-wall flashing, and step flashing.

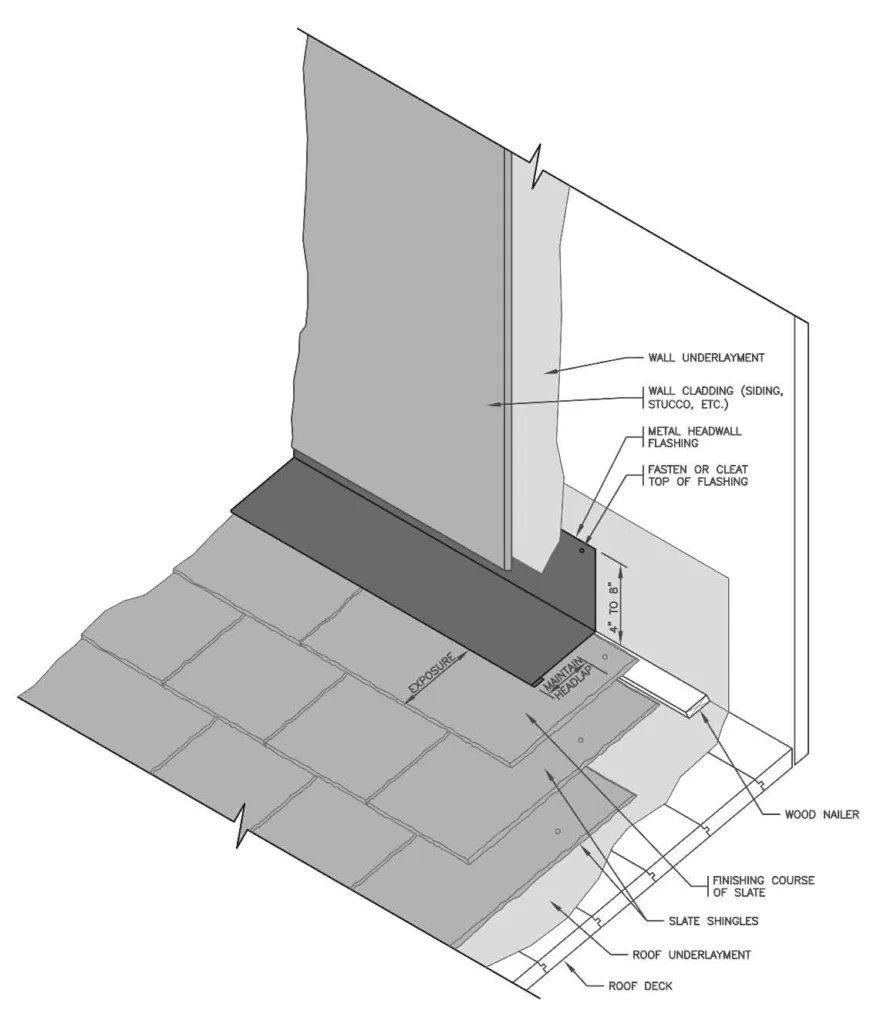

L flashing, also known as headwall or apron flashing, is used at the junction between a sloped roof and a vertical wall. It is a piece of flashing that is placed behind the exterior cladding on the wall and extended out over the shingles. The wall side of the flashing can be covered with siding or counter-flashing, and outside closures are necessary to seal between the flashing and the panel.

End-wall flashing is used where the upward slope of a roof meets a wall. This type of flashing is applied to the vertical surface of the wall and extends up under the shingles. The flashing is then covered with shingles to ensure that water flows away from the wall.

Step flashing is used for roof to wall flashing. It is a rectangular piece of flashing that is bent 90 degrees in the center. Multiple pieces of the flashing are installed in layers with shingles to ensure that water flows away from the wall. Step flashing is commonly used in areas where the slope of the roof changes direction.

When choosing the type of headwall flashing to use, it is important to consider the pitch of the roof. Different types of flashing are designed to work with different roof pitches. It is also important to ensure that the flashing is installed correctly to ensure that it provides effective protection against leaks and water damage.

Headwall flashing is an essential component of any roofing system. It helps to prevent water from penetrating the junction between the roof and the vertical wall, which can cause leaks and water damage. There are several different types of headwall flashing available, each designed for a specific application. It is important to choose the right type of flashing for your roof and to ensure that it is installed correctly to provide effective protection.

Understanding the Purpose of Headwall Flashing

Headwall flashing is a crucial component in roofing systems that helps prevent water from entering a building through the junction where a roof meets a vertical headwall. It is installed where a roof butts against a wall or where two roofs meet at a rigt angle. The flashing is called “headwall” because it is positioned at the top or head of the wall.

Headwall flashing is typically made of metal, such as aluminum or galvanized steel. The flashing is bent to fit the angle of the wall and the roof and is then installed over the top of the shingles or other roofing material. The flashing is secured in place with nails or screws and then sealed with roofing cement or other sealant.

The purpose of headwall flashing is to create a watertight seal between the roof and the wall. Without flashing, water can seep into the building through the junction between the roof and the wall, causing damage to the interior of the building and the roof structure.

To ensure that headwall flashing is installed correctly and provides adequate protection against water infiltration, it is important to hire a qualified roofing contractor. The contractor should have experience in installing flashing and be familiar with the roofing materials being used. A poorly installed flashing can compromise the integrity of the roofing system and lead to costly repairs in the future.

Headwall flashing is an essential component of a roofing system that prevents water from entering a building through the junction between the roof and the wall. It is made of metal, is installed over the shingles or roofing material, and is secured in place with nails or screws and sealant. A qualified roofing contractor should be hired to ensure that the flashing is installed correctly and provides adequate protection against water infiltration.

Where Should Headwall Flashing Be Installed?

Headwall flashing, also known as “L” flashing, is a crucial component in roofing systems. It is designed to prevent water from entering the junction beteen a sloped roof and a wall. The flashing is typically made of metal and is installed behind the exterior cladding on the wall.

The headwall flashing is installed by securing it to the wall with fasteners or adhesives. It is then extended out over the shingles on the roof. This creates a barrier that prevents water from seeping into the joint between the wall and the roof.

Headwall flashing is typically installed on roofs with a steep pitch or on roofs with a low-pitched slope where water runoff is more likely to be a problem. It is also installed on roofs where the wall extends above the roofline, such as on a dormer or a chimney.

Headwall flashing is installed at the junction between a sloped roof and a wall to prevent water from entering the joint. It is installed behind the exterior cladding on the wall and extended out over the shingles on the roof.

Endwall Flashing: An Overview

End-wall flashing is a type of flashing used where a roof meets a vertical wall. The primary function of end-wall flashing is to prevent water from seeping into the building through the intersection of the roof and wall.

The flashing is installed on the wall side of the intersection and is designed to channel water away from the joint. It is commonly made of metal, such as aluminum or galvanized steel, and is avilable in various widths and lengths to fit different roof pitches and wall heights.

To ensure a proper seal, outside closures are installed between the flashing and the metal roof panel. These closures are typically made of foam and are designed to fit the profile of the panel, preventing water and debris from entering the joint.

End-wall flashing is available in different styles to accommodate various types of siding or counter-flashing. It is important to specify the appropriate trim piece and roof pitch when ordering end-wall flashing to ensure proper fit and function.

End-wall flashing is a crucial component in protecting buildings from water damage at the intersection of the roof and wall. Its installation should be done with care and attention to detail to ensure maximum efficiency.

Understanding Roof To Wall Flashing

Roof to wall flashing is a crucial component of any roofing system, as it helps to prevent water from seeping into the structure of the building. The flashing used for this purpose is commonly known as step flashing. Step flashing is a rectangular piece of metal flashing that is bent at a 90-degree angle in the center. This allows it to be installed in a stepped pattern alng the junction between the roof and the wall, ensuring that water is directed away from the wall and towards the roof.

Step flashing is typically installed in multiple layers along with shingles, creating a water-resistant barrier that helps to protect the building from moisture damage. The flashing is designed to be durable and long-lasting, withstanding exposure to the elements and providing reliable protection against water intrusion.

Proper installation of step flashing is essential to ensure that the roofing system performs effectively. This involves careful placement of the flashing, ensuring that it is positioned correctly and sealed tightly against the wall and the roof. Additionally, it is important to use high-quality materials and work with a skilled roofing professional to ensure that the flashing is installed correctly and performs effectively over the long term.

Roof to wall flashing is commonly called step flashing, and it is a key component of any roofing system. By directing water away from the wall and towards the roof, step flashing helps to protect the building from moisture damage and maintain its structural integrity.

The Purpose of Headwalls

Headwalls are an essential component of retaining walls that are employed in various waterway projects. They are used to provide support for bridges and roadways by anchoring the piping to prevent movement due to hydraulic and soil pressures. The primary function of headwalls is to prevent soil erosion and scouring from turbulent storm-water.

Headwalls are usually found near streams, ponds, or similar waterways where the water flow needs to be controlled. They are designed to absorb the forces generated by the water flow and prevent the erosion of the surrounding soil. Headwalls are also used to prevent the undermining of bridges and other structures that are built near the waterways.

Some of the most common applications of headwalls include:

– Support for bridge abutments and piers

– Protection against erosion and scouring

– Control of water flow

– Anchoring of piping systems

– Prevention of soil movement due to hydraulic and soil pressures

– Stabilization of the surrounding soil

Headwalls can be made from a variety of materials, including concrete, stone, and metal. Concrete headwalls are the most popular beause of their strength, durability, and low cost. Stone headwalls are also popular, but they are more expensive and require more maintenance. Metal headwalls are used in situations where high strength is required, but they are susceptible to corrosion and require regular maintenance.

Headwalls are used to provide support for bridges and roadways, prevent soil erosion and scouring, stabilize the surrounding soil, and control water flow. They are an essential component of retaining walls in waterway projects and can be made from various materials depending on the specific application.

What is the Origin of the Term ‘Headwall’?

In the field of medicine, a headwall is a term used to descibe the wall located at the head end of a hospital bed space. The term “headwall” is derived from the fact that it is installed at the head of the bed, and typically features a range of medical equipment to support patient care.

The primary purpose of a headwall is to provide easy access to essential medical equipment and utilities required for patient care. These may include electrical outlets, oxygen and vacuum outlets, medical gas outlets, and communication systems. Additionally, a headwall may feature storage compartments, lighting, and other built-in features that enhance the functionality and efficiency of the hospital bed space.

The design of a headwall is typically tailored to meet the specific needs of the patient and the healthcare facility. Some headwalls are designed to accommodate specific medical equipment, such as cardiac monitors or respiratory support devices, while others are designed to provide a more general set of features to support a wider range of medical needs.

The term “headwall” is used to describe a critical component of modern hospital bed spaces that are essential to providing high-quality patient care.

Where Should Flashing Be Installed?

Flashing is the material used to protect your home from water damage. It is installed around the roof, windows, doors, and other areas where water can seep in. When it comes to gutters, flashing is typically installed behind the gutter and against the fascia board.

This is because flashing needs to be installed in such a way that it prevents water from seeping behind the gutter and damaging the fascia and soffit boards. If flashing is installed inside the gutter, it can actually trap water and lead to more problems down the line.

To ensure proper installation of flashing, it is recommended to work with a professional who has experience with gutter installation and waterproofing. They will be able to assess your home’s unique needs and install flashing in the appropriae location to protect your home from water damage.

Flashing should be installed behind the gutter and against the fascia board to prevent water damage to your home’s infrastructure.

Minimum Slope Requirements for Head Flashing

The head flashing is a crucial element of a properly installed window, as it helps to prevent water from seeping into the building. One of the key requirements for a head flashing is that it must have a minimum slope of 15° towards the exterior. This slope ensures that any water that does make its way onto the flashing will flow away from the building rather than pooling and potentially causing damage. Additionally, the head flashing should be fixed againt the cavity battens and overhang the window by at least 30 mm at each end. These requirements help to ensure that the flashing provides effective protection against water infiltration and helps to maintain the integrity of the building envelope.

Should Shingles Be Flashed?

Flashing is an essential component of any roofing system as it helps to prevent water from penetrating the roof and entering the home. There are different types of flashing, including step flashing, continuous flashing, and drip edge flashing. The question of whether flashing should be uner shingles is a common one, and the answer is yes.

When installing shingles, it is crucial to ensure that the flashing is installed correctly. The flashing should be installed under the shingles and extend up the sidewall of the home. This is known as step flashing and is required by all shingle manufacturers, including asphalt, wood, and slate.

Step flashing is typically made of metal and is designed to fit snugly against the sidewall of the home. The shingles are then installed over the flashing, with each shingle overlapping the previous one. This creates a watertight seal that prevents water from entering the home.

In addition to step flashing, other types of flashing may be used to protect the roof, such as continuous flashing and drip edge flashing. Continuous flashing is a single piece of metal that is installed over the entire roof edge, while drip edge flashing is installed along the eaves to direct water away from the roof.

Flashing should be installed under shingles to create a watertight seal and prevent water from entering the home. Step flashing is the most common type of flashing used for this purpose and is required by all shingle manufacturers.

Types of Roof Flashing

Roof flashing is an essential component of a roofing system. It is installed at the intersections of roof planes and vertical surfaces, such as chimneys, skylights, and walls, to prevent water from entering the building. There are several types of roof flashing, each designed for a specific purpose. Here are the most common types of roof flashing:

1. Counter flashing: This type of flashing is installed over the top of a base flashing and is designed to protect the base flashing from water intrusion. It is commonly used on masonry chimneys and walls.

2. Chimney flashing: Chimney flashing is installed around the base of a chimney to prevent water from entering the roof system. It typically consists of step flashing, counter flashing, and a cricket or saddle to divert water around the chimney.

3. Step flashing: Step flashing is used at the intersections of roof planes and vertical surfaces, such as walls and chimneys. It is installed in a series of steps, with each piece overlapping the previous one, to create a watertight barrier.

4. Headwall flashing: Headwall flashing, also known as apron flashing, is installed along the bottom edge of a roof whre it meets a vertical wall. It is designed to prevent water from entering the building at this critical junction.

5. Valley flashing: Valley flashing is installed in the valley between two roof planes to prevent water from entering the roof system. It is often made of metal and is installed in a continuous piece.

6. Gutter apron flashing: Gutter apron flashing is installed along the edge of the roof to prevent water from entering the building behind the gutter. It is typically installed in conjunction with a drip edge to create a watertight barrier.

Roof flashing is an essential component of any roofing system. There are several types of roof flashing, each designed for a specific purpose, including counter flashing, chimney flashing, step flashing, headwall flashing, valley flashing, and gutter apron flashing. By understanding the different types of flashing, you can ensure that your roof system is watertight and protected from water intrusion.

Uses of Z Flashing

Z flashing, also known as Galvanized Steel Z-Flashing, is a type of metal flashing used in construction to protect horizontal joints betwen sheets of siding from water infiltration. Its primary purpose is to prevent water from seeping behind the siding and causing damage to the structure of the building.

Z flashing is particularly important in areas with high rainfall or in buildings located in areas with harsh weather conditions. It is made from 28-gauge galvanized steel, which provides durability and resistance against rust and corrosion.

When installed correctly, Z flashing creates a barrier that prevents water from getting behind the siding and causing damage to the wall or the interior of the building. The large leg of the metal is placed against the wall, while the seat and face cover the top edge of the siding, creating an overlapping seal that prevents water from seeping through.

Z flashing can be used in a variety of applications, including around windows, doors, and other openings in the building’s outer shell. It is particularly useful in areas where the siding meets the roofline or where different types of siding or cladding materials meet.

Z flashing is a crucial element in construction that helps protect buildings from water damage. It is made from galvanized steel and is used to cover horizontal joints between sheets of siding. Proper installation of Z flashing can prevent water infiltration and ensure the long-term durability of a building.

The Function of Thru Wall Flashing

Through-wall flashing is a technique used to prevent water from penetrating into the walls of a building. This flashing method is the most effective way to prevent leaks, except in areas exposed to earthquakes. The flashing is installed at the base of the wall and extends up to the height where the wall meets the roof. This method is used in both residential and commercial buildings.

The flashing is typically made of metal, such as copper, aluminum, or stainless steel. The metal is chosen for its durability and resistance to corrosion. The flashing is installed in a way that it diverts water away from the wall and toward the outside of the building. This prevents water from entering the wall and causing damage to the structure.

Through-wall flashing is essential for buildings that are located in areas with heavy rainfall or snow. Water can penetrate into the walls trough cracks or gaps in the masonry. Over time, this can cause damage to the building, including rotting of wood, mold growth, and structural damage. Through-wall flashing prevents this from happening by diverting the water away from the wall.

In addition to preventing water from entering the wall, through-wall flashing also helps to ventilate the wall cavity. This is important because it allows moisture to escape from the wall, preventing the growth of mold and mildew.

To install through-wall flashing, the wall must be opened up at the base. The flashing is then installed and sealed to the wall using waterproofing materials. The wall is then closed up, and the flashing is painted or covered to match the rest of the building.

Through-wall flashing is an essential technique for preventing water damage to buildings. It is a highly effective method of diverting water away from the wall and preventing moisture from entering the building.

The Benefits of Using the Best Type of Roof Flashing

When it comes to choosing the best type of roof flashing, there are severl materials to consider. The three most popular materials for roof flashing are aluminium, copper, and stainless steel. Each of these materials has its own advantages and disadvantages, and choosing the right one depends on several factors.

Aluminium is a durable and versatile material that is suitable for numerous flashing locations, including in the valleys, around the chimney, and at the walls or step-up areas. It is lightweight, easy to work with, and affordable. Aluminium flashing is also resistant to rust and corrosion, making it a great choice for areas with high moisture levels.

Copper is a pricier, highly durable flashing option, but it offers several benefits. Copper flashing has a long lifespan and can last up to 100 years, making it an excellent investment for homeowners who want a long-term solution. It is also resistant to corrosion and can withstand extreme weather conditions. Copper flashing is commonly used in historical or high-end homes due to its aesthetic appeal.

Stainless steel is another popular option for roof flashing. It is highly durable, resistant to corrosion, and can withstand the elements. Stainless steel flashing is commonly used in commercial buildings and industrial settings due to its strength and durability. It is also fire-resistant and can help prevent fires from spreading through the roof.

When choosing the best type of roof flashing, it’s important to consider the location, budget, and desired lifespan of the flashing. Aluminium is a great option for those on a budget or looking for a shorter-term solution. Copper is a great investment for those looking for a long-lasting and aesthetically pleasing option. stainless steel is ideal for those looking for a strong and durable option that can withstand extreme weather conditions.

The Benefits of a Gap Between Roof and Wall

When it comes to construction, it’s important to ensure that all components of a building are properly designed and installed. One question that often arises is whether there should be a gap between the roof and the wall. The short answer is yes, there should be a gap between the roof and the wall.

The purpose of this gap is to allow for ventilation. Without proper ventilation, moisture can build up in the roof space, leading to problems such as mold growth, wood rot, and structural damage. A gap between the roof and the wall allows air to flow freely and help prevent these issues.

However, it’s important to note that this gap should be covered with a material that allows ventilation but keeps out small animals and rodents. Materials such as aluminum or vinyl with screens are often used for this purpose. Additionally, the size of the gap will depend on the specific building design and climate conditions.

A gap between the roof and the wall is necessary for proper ventilation and to prevent moisture buildup. This gap should be covered with a suitable material to allow ventilation wile keeping out small animals and rodents.

Conclusion

Headwall flashing is an essential component of any roofing system. It is designed to prevent water from penetrating the junction between a sloped roof and a vertical headwall. By directing the flow of water away from the wall, headwall flashing helps to prevent damage to the roof and the building structure.

There are different types of headwall flashing, including L flashing and step flashing, each with its specific application. When choosing headwall flashing, it’s crucial to consier the roof pitch and the type of exterior cladding used.

Proper installation is key to ensuring that headwall flashing performs effectively. It’s essential to use high-quality materials and to follow the manufacturer’s installation instructions carefully. Regular maintenance and inspection of headwall flashing are also vital to prevent leaks and other problems.

Headwall flashing is an essential part of protecting your building from water damage. By choosing the right type of flashing and installing it correctly, you can ensure that your roof remains watertight and secure for years to come.