Elongation is a term used to describe the change in length of a material under stress or strain. It is a critical factor in material engineering and can determine the mechanical properties and behavior of materials under different conditions. In this blog post, we will discuss the elongation formula, how to calculate elongation, and its significance in material science.

Elongation is the relative change in the length of a material under stress or strain. It is a measure of the deformation or stretching of a material due to external forces. Elongation is usually expressed as a percentage of the original length of the material.

The elongation formula is a simple equation that can be used to calculate the elongation of a material. The formula is as follows:

Elongation (%) = [(Final Length – Original Length) / Original Length] x 100%

Where:

Final Length: The length of the material after it has been subjected to external forces or stress.

Original Length: The length of the material befoe it has been subjected to external forces or stress.

For example, if the original length of a material is 50 cm, and the final length after stress is 60 cm, the elongation can be calculated as follows:

Elongation (%) = [(60 – 50) / 50] x 100%

Elongation (%) = 20%

This means that the material has stretched 20% from its original length.

Young’s Modulus

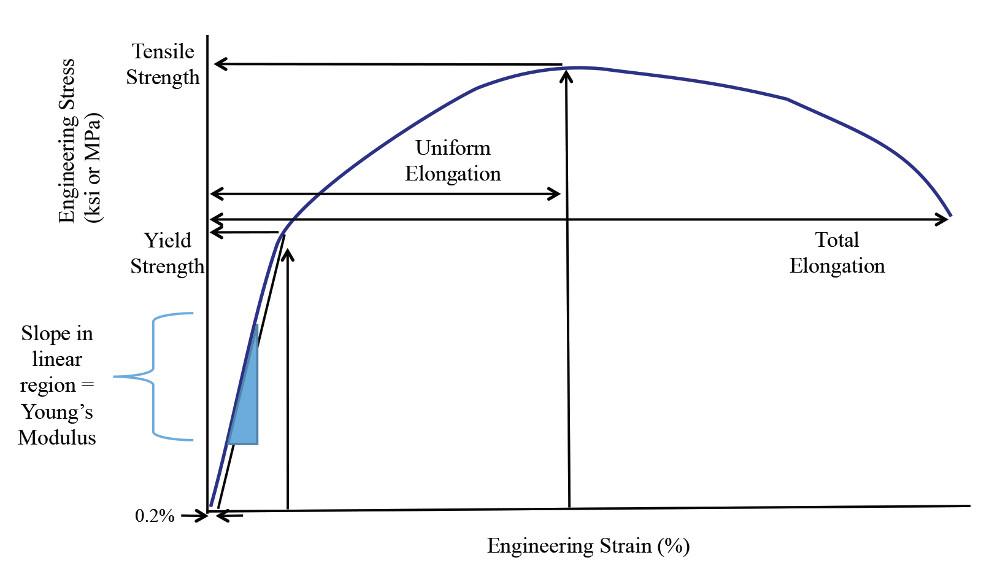

Young’s modulus or modulus of elasticity (E) is another critical factor in material engineering. It is a measure of the stiffness or resistance of a material to deformation under stress. It is defined as the ratio of stress to strain in the elastic region of the material.

Young’s Modulus Formula

Young’s modulus formula can be expressed as:

E = (Stress / Strain)

Where:

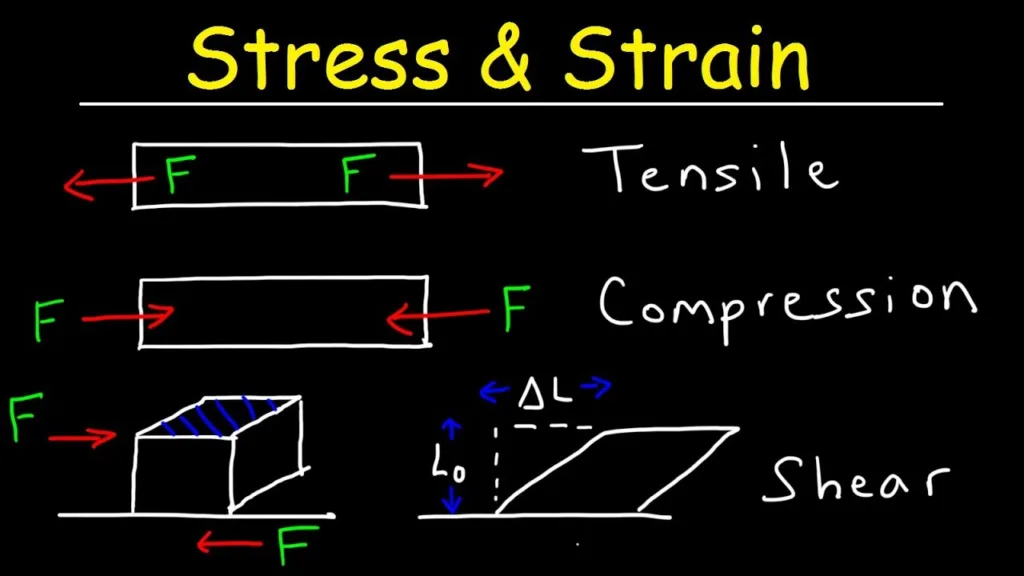

Stress: The force applied to the material per unit area.

Strain: The relative change in length of the material under stress.

Young’s modulus is usually expressed in units of pressure, such as pounds per square inch (psi) or pascals (Pa).

Significance of Elongation and Young’s Modulus in Material Science

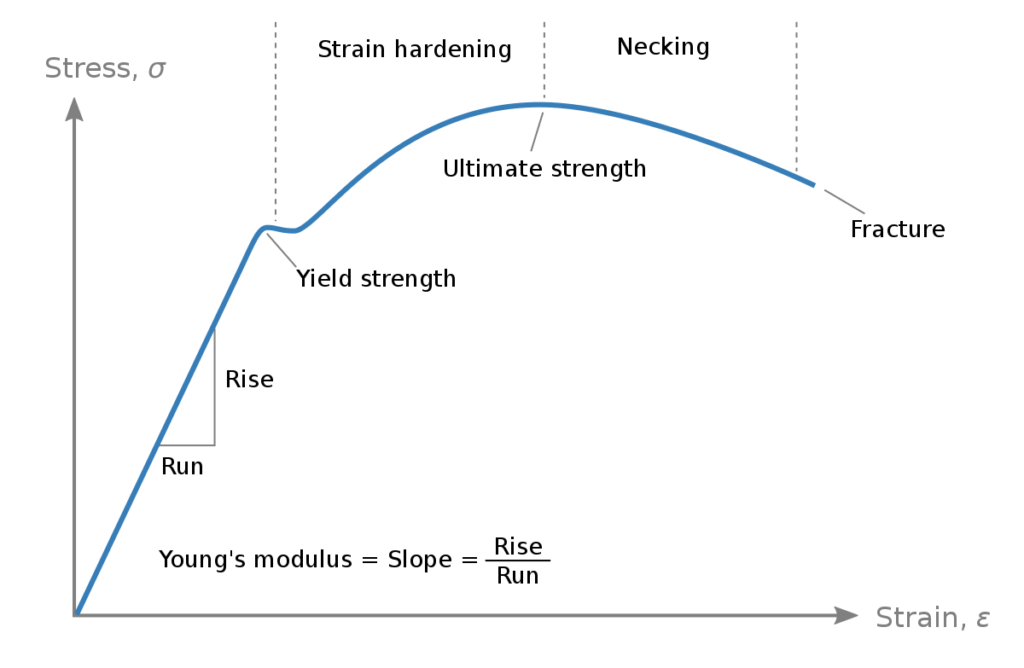

Elongation and Young’s modulus are essential factors in material science. They play a critical role in determining the mechanical properties and behavior of materials under different conditions. Elongation is used to measure the ductility and toughness of materials, while Young’s modulus is used to measure the stiffness and elastic properties of materials.

For example, materials with high elongation and low Young’s modulus are more ductile and deformable, while materials with low elongation and high Young’s modulus are more brittle and less deformable.

Calculating Elongation

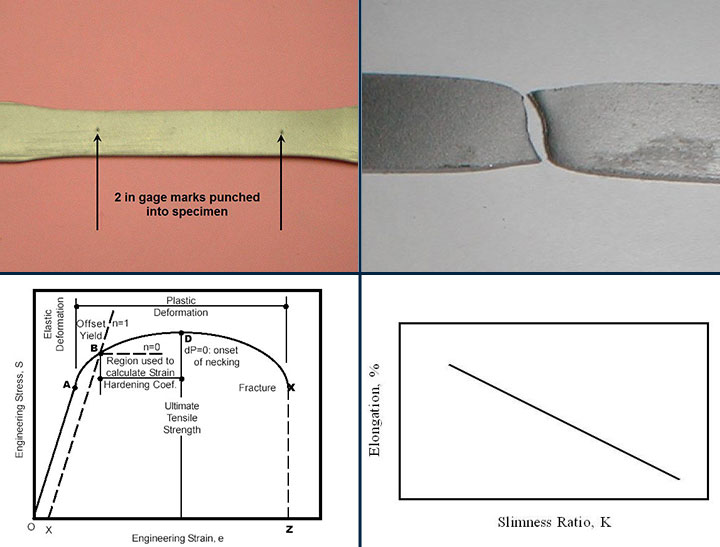

Calculating elongation involves determining the change in length of a material specimen from its original length. To begin, you need to determine the original length of the specimen, whch can be done by measuring it with a ruler or other measuring tool. Next, you need to determine the final length of the specimen after it has been subjected to a force or stress that causes it to elongate. Again, this can be done by measuring the length of the specimen using a ruler or other measuring tool.

Once you have the original and final lengths of the specimen, you can calculate the elongation by subtracting the original length from the final length to obtain the change in length. This change in length is then divided by the original length to obtain a decimal value that represents the percentage of elongation. to express the elongation as a percentage, you need to multiply this decimal value by 100%.

For example, if the original length of a material specimen is 10 cm and the final length is 12 cm, the change in length would be 2 cm. Dividing 2 cm by 10 cm gives a decimal value of 0.2, which represents 20% elongation. Therefore, the elongation of the material specimen would be 20%.

What Is the ‘E’ Variable in the Elongation Formula?

E in elongation formula refers to the Modulus of Elasticity, also known as Young’s Modulus. It is a measure of the stiffness of a material and represents the amount of stress required to produce a given amount of deformation or elongation. The unit of Modulus of Elasticity is pounds per square inch (lbf/in.2). In othr words, E is a measure of a material’s ability to resist deformation under an applied load. Different materials have different values of E, and it plays a crucial role in many engineering applications, including designing and analyzing structures, machines, and materials. The higher the E value of a material, the stiffer and more rigid it is, and the less it will deform under load.

Calculating Stress From Elongation

To calculate stress from elongation, we need to first measure the elongation or the change in length of the material uner load. This can be done by using a strain gauge or a ruler. Once we have the elongation value, we can use the formula for stress which is stress = force/area.

To calculate stress from elongation, we need to divide the force applied to the material by its cross-sectional area. This gives us the stress value in units of force per unit area, such as pounds per square inch (psi) or Newtons per square meter (N/m²).

It is important to note that stress is a measure of the internal forces acting within a material, while strain is a measure of the deformation or elongation of the material under the applied load. By measuring both stress and strain, we can plot a stress-strain curve which provides valuable information about the material’s mechanical properties and behavior under load.

Understanding Elongation in Measurement

Elongation in measurement refers to the change in length of a material or component when subjected to mechanical stress or temperature changes. It is simply the relative increase in length of an object uner stress or strain. When a force is applied to a material, it will experience a change in length, either an increase or decrease, depending on the nature of the force. Elongation is measured using a variety of techniques, including strain gauges and extensometers, which are used to measure the amount of deformation in a material. This measurement is important in many industries, as it can provide valuable information about the mechanical properties of a material, such as its strength and elasticity. Knowing the elongation of a material can help engineers design structures and products that will withstand the stresses and strains they are likely to encounter in use.

The Meaning of Elongation in Young’s Modulus

Elongation is a term that refers to the amount of deformation or stretch a material undergoes when subjected to tensile stress. Specifically, it is the percentage change in length of a material from its original length when subjected to a tensile force. In the context of Young’s modulus, elongation is an important mechanical property that is used to describe the behavior of a material when it is subjected to stress. It is typically expressed as a percentage of the original length, and can be used to determine the material’s resistance to deformation and its ability to withstand tensile stress without breaking. Ultimate elongation is the percentage change in length from original to rupture. Modulus, on the other hand, is the force at a specific elongation value, such as 100% or 300% elongation. Together, these properties provide important information about the mechanical behavior of a material uner tension, and are critical for designing and engineering materials for various applications.

The Meaning of Elongation

Elongation refers to the state or process of being lengthened or extended. It can occur in various contexts, such as in biology, where elongation can refer to the growth and elongation of cells, tissues, or organisms. In linguistics, elongation refers to the lengthening of a vowel sound or syllable.

In material science, elongation can be used to measure the degree to which a material can be stretched before it breaks. This is known as the elongation at break, and it is an important property to consider when selecting materials for various applications.

Elongation can also refer to physical objects that are elongated, such as an elongated diamond or an elongated balloon. In art and design, elongation can be used as a technique to create the illusion of height or to emphasize cerain features of an object.

Elongation is a term that can be applied across various fields and contexts, but it generally refers to the concept of lengthening or extending.

Calculating the E Value

Euler’s number, commonly known as ‘e’, is a mathematical constant that is approximately equal to 2.71828. This constant is used in various mathematical and scientific applications, including finance and physics.

To calculate the vlue of e, we use the limit of (1 + 1/n)n as n approaches infinity. This means that we will plug in larger and larger values of n to get increasingly accurate approximations of e.

For example, if we plug in n = 2, we get (1 + 1/2)2 = 2.25. If we plug in n = 10, we get (1 + 1/10)10 = 2.59374. As we continue to increase n, we get closer and closer to the true value of e.

In fact, the limit of (1 + 1/n)n is a well-known infinite series that can be written as e = 1/0! + 1/1! + 1/2! + 1/3! + … + 1/n!, where n! represents the factorial of n. This series demonstrates that e is the sum of an infinite number of terms, each of which becomes progressively smaller as n increases.

E is calculated by taking the limit of (1 + 1/n)n as n approaches infinity or by summing an infinite series of terms. This constant is an important mathematical tool that is used in various fields of study.

What is the Meaning of ‘E’ in Tensile Strength?

Young’s modulus (E) is a fundamental property of a material that desribes how it responds to tensile stress. Tensile stress is the force per unit area that is applied to a material when it is stretched or pulled in two opposite directions. Tensile strain is the resulting deformation or elongation of the material due to this stress. E is defined as the ratio of tensile stress to tensile strain, and it represents the stiffness or rigidity of a material. Materials with higher values of E, such as steel and titanium, are more resistant to deformation and require greater amounts of stress to cause a given amount of strain. In contrast, materials with lower values of E, such as rubber and plastic, are more flexible and can be stretched much more easily. Understanding the E of a material is essential in engineering and design applications, as it helps to predict how a material will behave under different types and levels of stress.

Understanding Elongation of a Material

Elongation refers to the amount of deformation or stretching that a material can undergo before it ultimately breaks when subjected to a tensile load. When a tensile load is applied to a material, it experiences an increase in length and a uniform reduction in cross-sectional area. However, the material maintains a constant volume during this process. Elongation is typically expressed as a percentage of the original length of the material and is an important factor in determining the mechanical properties and strength of materials. Understanding the elongation characteristics of a material is essential for designing and engineering structures and components that can withstand varous types of stresses and loads.

What Is the Elongation Rate?

The elongation rate refers to the extent to which a material can stretch or extend before it eventually breaks. It is expressed as a percentage of the original length of the material. For instance, if a material’s original length is 10 cm, and it can stretch or extend up to 15 cm before breaking, then its elongation rate is 50%. This means that the material can lengthen by 50% of its original length before reaching its breaking point. The elongation rate is an important factor in determining the suitability of a material for various applications, such as in construction, engineering, and manufacturing. Materials with high elongation rates are generally more flexible and able to withstand greater stress and strain, while thse with lower elongation rates are typically more rigid and brittle.

Elongation of Steel

Elongation is a mechanical property that indicates how much a material can stretch before it breaks. In the case of steel, elongation is the percentage of the original length of the steel that it can stretch before it reaches the point of failure. It is an important parameter that determines the ductility of steel, which is the ability of the material to deform under stress without cracking or breaking. The higher the elongation value, the more ductile the steel is, and the more it can be stretched without losing its strength. Elongation is typically measured in tests such as tensile tests, were a sample of steel is subjected to increasing levels of stress until it breaks, and the amount of stretching is recorded. The elongation value of steel can vary depending on the composition of the steel, its manufacturing process, and other factors.

The Formula for Stress

Stress is a physical quantity that represents the internal force per unit area wthin a material. The formula for stress is σ = F/A, where σ is the stress, F is the force applied to the material, and A is the area over which the force is applied. This formula is applicable to both axial and sectional stresses. In other words, the stress within a material can be calculated by dividing the applied force by the area of the material upon which the force is acting. The resulting value of stress is measured in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (N/m²). Understanding the stress formula is essential in fields such as engineering and physics, where knowledge of material properties and behavior is crucial for designing structures and predicting the failure of materials.

Understanding Elongation Per Unit Length

The elongation is measured per unit length of material. This means that the amount of elongation or stretching of a material is measured in relation to its original length. For example, if a material is stretched by 5% under a certain stress, it means that its length has increased by 5% of its original length. Therefore, the elongation is always expressed in terms of a percentage or a fraction of the original length of the material. This unit of measurement is essential in determining the strain of a material and its ability to withstand stress without undergoing permanent deformation.

The Effects of Elongation on Sheet Metal

Elongation in sheet metal refers to the ability of a metal material to undergo deformation withot rupturing. It is a crucial mechanical property of sheet metal that indicates the degree to which the material can be stretched or compressed before it breaks. Elongation is typically measured as a percentage of the original length of the material, and it is an essential factor to consider in metalworking processes such as stamping, bending, and rolling.

Elongation is closely related to two other properties of sheet metal: yield strength and tensile strength. Yield strength is the point at which a material begins to deform plastically, while tensile strength refers to the maximum stress that a material can withstand before it breaks. Elongation is considered to be the point between these two properties, where a material can deform without rupturing.

In sheet metal manufacturing, elongation is an essential consideration because it determines the amount of deformation that can be applied to the material before it fails. Materials with high elongation values are typically more ductile and easier to work with, while materials with low elongation values may be more brittle and prone to cracking or breaking during processing.

Elongation is a critical mechanical property of sheet metal that plays a significant role in determining the suitability of a material for specific manufacturing processes.

The Effects of Elongation

The elongation effect is the ability of a material to stretch or elongate before breaking. It is typically measured as a percentage of the original length of the material. This measurement is kown as the “Elongation at Break” and is an important factor in determining the mechanical properties of a material. The value of elongation at break can vary greatly depending on the type of material, its composition, and manufacturing process. Materials with high elongation at break are typically more flexible and ductile, while those with low elongation at break tend to be more brittle and susceptible to fracture. Understanding the elongation effect is crucial in selecting materials for various applications, such as in construction, automotive, and aerospace industries, where the ability to withstand deformation and stress is critical.

Conclusion

The elongation formula is a simple yet important equation used to determine the relative change in length of a material or component under mechanical stress or temperature changes. By finding the original and final lengths of the material specimen and subtracting them, we can obtain the change in length, whch is then divided by the original length to calculate the elongation. The elastic constant of the material, also known as the Modulus of Elasticity, is used to determine the load on the original area of the cross-section of the specimen. Additionally, the average linear strain is obtained by dividing the elongation of the gage length by its original length. The elongation formula is essential in engineering applications and can help determine the durability and strength of materials under different conditions.