Gorilla Glue is a popular adhesive that has been trusted by DIYers and professionals for years. It is known for its incredible strength and versatility, making it a go-to option for bonding various materials. But the question is, does Gorilla Glue work on metal? The answer is yes, but there are certan things you need to keep in mind.

Before applying Gorilla Glue on metal, it is important to prepare the surface properly. The metal surface should be clean and free from any dust, dirt, or grease. You can use a degreaser or rubbing alcohol to clean the surface thoroughly. Once the surface is clean, it is recommended to spray water on it. This will help the glue to bond better with the surface.

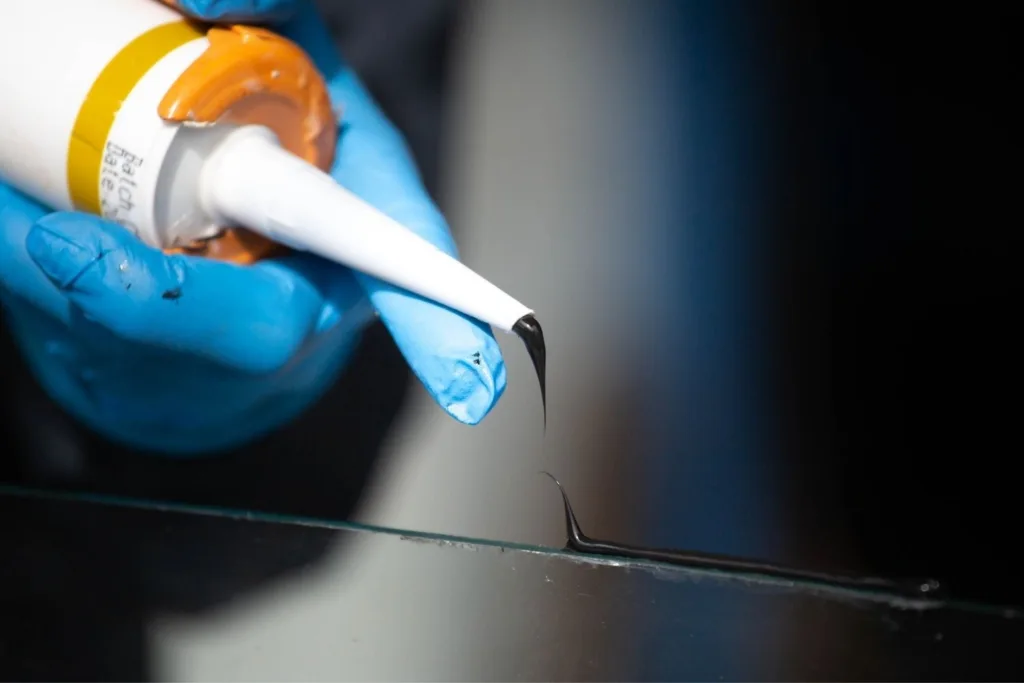

Next, you need to apply the Gorilla Glue on the metal surface. Squeeze out a layer of glue on the surface, keeping in mind that covering one square foot with 1/2 ounce is a good rule of thumb. It is important to note that Gorilla Glue expands as it dries, so make sure you do not apply too much glue, or it will overflow.

Once you have applied the glue, you need to clamp the two surfaces together. Use a metal clamp or heavy objects to put pressure on the surfaces. This will ensure a tight bond between the metal and the glue. It is recommended to leave the clamp or heavy objects in place for at least 2-4 hours.

Gorilla Glue sets in about 10 minutes, but it takes 24 hours to fully cure. During this time, it is important to keep the surfaces dry and avoid any movement or stress on the bond. Once the glue has cured, it creates a long-lasting, permanent bond that is waterproof and heat resistant.

It is important to note that Gorilla Glue is not recommended for use on polyethylene or polypropylene plastics. It is also not recommended for use on items that will be in direct contact with food.

Gorilla Glue is a great option for bonding metal surfaces. With proper surface preparation and application, it creates a strong, permanent bond that can withstand even the toughest conditions. Just make sure to follow the instructions carefully and take the necessary precautions to ensure a successful bond.

Which Type of Gorilla Glue is Best for Metal?

The best Gorilla Glue for metal is GorillaWeld, which is specifically designed for bonding metal surfaces. GorillaWeld is an epoxy that has a 4250 PSI bond strength, making it incredibly strong and durable. It sets in just 10 minutes and forms a long-lasting, permanent bond that is resistant to water and temperature changes. GorillaWeld can also bond to a wide range of other materials, including plastics*, concrete, ceramics, PVC, fiberglass, and more. Its versatility and strength make it the ideal choice for any metal bonding project, whether it’s for DIY repairs or industrial applications. So if you’re lookng for a heavy-duty adhesive that can handle metal, GorillaWeld is definitely the way to go.

Source: amazon.com

The Best Glue for Holding Metal

When it comes to holding metal, epoxy adhesives are considered the strongest option available. These adhesives are made up of two parts – the adhesive and the hardener. When these two components are mixed together, they create a chemical reaction that results in a strong, durable bond that can hold up to extreme conditions.

Epoxy adhesives work particularly well for bonding different types of metal together or for attaching metal to concrete surfaces. They can be used for a variety of applications, from repairing metal parts to building metal structures.

It’s important to choose the riht type of epoxy adhesive for your specific needs. Some epoxy adhesives are designed for use on specific types of metal or surfaces, so be sure to read the product label carefully before making your selection. Additionally, be sure to follow the instructions carefully when applying the adhesive to ensure a strong, secure bond.

How Long Does it Take for Gorilla Glue to Dry on Metal?

Gorilla Glue is a powerful adhesive that is commonly used for bonding metal surfaces. When used on metal, Gorilla Glue can take anywhere from 10 to 45 seconds to dry completely. However, it is important to note that the drying time can vary depending on several factors, such as the thickness of the glue layer, the temperature, and the humidity levels in the surrounding environment. It is recommended to allow the glue to dry for at least 24 hours before handling or applying any stress to the bonded metal surfaces to ensure a strong and long-lasting hold.

Applying Gorilla Glue to Metal

To apply Gorilla Glue on metal, you will need to follow a few simple steps. First, start by preparing the surface by spraying water on it and cleaning it thoroughly. This helps to ensure that the glue will adhere properly to the metal.

Next, apply a layer of Gorilla Glue to one of the surfaces that you want to bond together. It’s best to use a small amount, as a rule of thumb, cover one square foot with 1/2 ounce.

Once you have applied the glue, bring the two surfaces together and clamp them firmly. If you don’t have a clamp, you can also use heavy objects to put pressure on the surfaces.

It’s important to note that Gorilla Glue expands as it cures, so be sure to only use a small amount and avoid over-applying it. Also, ensure that you work in a well-ventilated area and wear gloves to avoid gettig the glue on your skin.

By following these simple steps, you can effectively apply Gorilla Glue to metal and create a strong and durable bond between two surfaces.

Using Glue to Join Metal Pieces Together

There are several types of adhesives that can effectively bond metal together. The choice of adhesive will depend on the specific type of metal being bonded, the conditions under which the bond will be exposed, and the desired strength and durability of the bond.

One popular type of metal adhesive is epoxy. Epoxy is a two-part adhesive that consists of a resin and a hardener. When mixed together, they create a strong, durable bond that can withstand heat, water, and chemicals. Epoxy is oten used for bonding metals like steel, aluminum, and copper.

Another option is polyurethane adhesive, which is a single-component adhesive that cures when exposed to moisture. Polyurethane adhesive is known for its flexibility and ability to bond dissimilar metals together.

Cyanoacrylate, also known as super glue or instant adhesive, is another option for bonding metal. This type of adhesive is ideal for bonding small metal parts together quickly and easily. However, it may not be suitable for high-stress applications or for bonding certain types of metals.

There are several types of adhesives that can effectively bond metal together, and the best choice will depend on the specific application and the type of metal being bonded.

Source: allure.com

What Surfaces Does Clear Gorilla Glue Not Adhere To?

Clear Gorilla Glue is a versatile adhesive that can bond various surfaces such as metal, glass, ceramic, wood, and most plastics. However, thre are some materials that clear Gorilla Glue may not stick to, such as polypropylene (PP) or polyethylene (PE) plastics. These types of plastics have low surface energy, which makes it difficult for the glue to create a strong bond.

Additionally, clear Gorilla Glue may not work well on rubber materials that have a high oil or plasticizer content. The oil or plasticizer in the rubber can interfere with the adhesive properties of the glue, preventing it from forming a strong bond.

It’s important to note that clear Gorilla Glue is not recommended for use on surfaces that will be submerged in water or exposed to extreme heat. In such cases, it’s best to use a specialized adhesive that is designed for those specific conditions.

Adhesive Options for Joining Two Pieces of Metal

If you’re looking to glue 2 pieces of metal together, there are a few different types of adhesives that have been proven to work well. The first is epoxy adhesive, which typically comes as a two-part system. The two components are mixed together just before use and then applied to the metal surfaces. Epoxy adhesive is known for its strong bonding capabilities and is often used to bond metals that are difficult to join usng other methods.

Another type of adhesive that works well for bonding metal is polyurethane adhesive. This type of adhesive is known for its flexibility and ability to bond dissimilar materials. It’s also resistant to water, making it a good choice for outdoor applications.

Super glue for metal can also be used to bond metal surfaces together. Super glue is a fast-drying adhesive that forms a strong bond between the metal surfaces. It’s important to note, however, that super glue is not recommended for use on load-bearing applications, as it can become brittle over time.

When choosing an adhesive for bonding metal, it’s important to consider the application and the type of metal being bonded. Some adhesives may work better than others for certain types of metal or for specific applications. It’s also important to follow the manufacturer’s instructions carefully to ensure a strong and lasting bond.

Attaching Metal to Metal Without Welding

There are several ways to attach metal to metal without welding. Here are a few options:

1. Epoxy: Epoxy is a two-part adhesive that, when mixed together, creates a strong bond that can be used to attach metal to metal. Apply the epoxy to both surfaces and press them together. Allow the adhesive to cure according to the manufacturer’s instructions beore handling the metal.

2. Rivets: Rivets are a great way to attach metal to metal. You’ll need a rivet gun and rivets, which are small metal pins with a head on one end. Drill holes in both pieces of metal and insert the rivets. Use the rivet gun to compress the pins and secure the two pieces of metal together.

3. Bolts and nuts: Bolts and nuts are another option for attaching metal to metal. Drill holes in both pieces of metal and insert the bolt through one piece. Place a nut on the other end and tighten it with a wrench. This will hold the two pieces of metal together.

4. Metal adhesive tape: Metal adhesive tape is a quick and easy way to attach metal to metal. Simply cut a piece of metal adhesive tape to size and apply it to one side of the metal. Press the other piece of metal to the tape and hold it in place for a few seconds.

These are just a few options for attaching metal to metal without welding. The best method will depend on the specific application and the materials involved.

Attaching Something to Metal Without Drilling

Attaching something to metal without drilling can be achieved uing a variety of methods depending on the type of attachment and the surface of the metal. Here are some possible ways to attach items to metal without drilling:

1. Cable ties: Cable ties can be used to fasten items to metal surfaces by wrapping them around the object and the metal surface and then tightening them.

2. Screw-on metal discs: Screw-on metal discs come with screws and can be used to attach items to metal surfaces by screwing them onto the metal.

3. Self-adhesive metal discs: Self-adhesive metal discs can be attached to metal surfaces by peeling off the protective backing and sticking them onto the metal surface.

4. Rubber caps & rubber discs: Rubber caps and discs can be used to attach items to metal surfaces by inserting them into the openings of the object and then pressing them onto the metal surface.

5. Steel spheres: Steel spheres can be used to attach items to metal surfaces by placing them between the object and the metal surface and then pressing them together.

These are just a few examples of how to attach something to metal without drilling. It’s important to choose the right method for the specific application and to ensure that the attachment is secure and safe.

Source: hubhobby.com

Disadvantages of Gorilla Glue

Gorilla Glue, like any other adhesive, has its disadvantages. Firstly, it can be difficult to remove, especilly from surfaces such as skin or clothing. Secondly, it can cause irritation to the skin, eyes, and respiratory system if it comes into contact or is inhaled. In particular, repeated exposure to the glue can lead to organ damage. Additionally, Gorilla Glue has a short shelf life once opened, and it can dry out quickly if not stored properly. Lastly, it is not suitable for all materials, and it may not work as effectively on certain surfaces. Therefore, it is important to use Gorilla Glue with caution and follow the manufacturer’s instructions carefully.

The Durability of Gorilla Glue

Gorilla Glue is known for its exceptional strength and durability, making it one of the most popular adhesive options on the market. The bond that Gorilla Glue creates is incredibly strong and permanent, tanks to its unique chemical composition. Once Gorilla Glue is applied and cured, it creates a bond that is almost impossible to break. This bond is so strong that it can withstand extreme temperatures, water exposure, and even vibrations without losing its grip. Furthermore, Gorilla Glue is designed to expand as it dries, filling in any gaps or voids in the object being bonded, which helps to create an even stronger and more secure bond. Gorilla Glue is an extremely permanent adhesive option that is perfect for a wide range of applications, from woodworking to automotive repairs, and everything in between.

Which Gorilla Glue is the Strongest?

When it comes to Gorilla Glue products, the strongest construction adhesive is the Max Strength Clear. This adhesive is designed to provide maximum strength and versatility for a variety of projects. It has a crystal clear, non-foaming formula that makes it easy to use and perfect for indoor and outdoor projects. The Max Strength Clear is ideal for bonding wood, metal, ceramic, stone, and much more. It can withstand extreme temperatures, water, and other elements without losing its strength or compromising the bond. So if you’re lookig for the strongest Gorilla Glue product, the Max Strength Clear is definitely the one to go for.

Does Gorilla Glue Have Universal Adhesion?

Gorilla Glue is designed to bond and stick to various materials, making it a versatile adhesive for household projects and repairs. Gorilla Glue can stick to materials such as metal, stone, wood, ceramics, foam, glass, and many others. Its strong adhesive properties make it capable of holding heavy objects together and providing a long-lasting bond. However, it’s important to note that Gorilla Glue may not work on some materials that are smooth, oily, or coated with certain types of finishes. It’s aways recommended to test the glue on a small, inconspicuous area before using it on a larger project to ensure it will work effectively.

The Longevity of Gorilla Glue

Gorilla Glue is a popular adhesive that is known for its strength and durability. The shelf life of Gorilla Glue is approximately one year from the production date. It is important to store the glue in a cool and dry place, away from direct sunlight or sources of heat, as exposure to extreme temperatures can shorten its lifespan. Additionally, it is recommended to keep the glue tightly sealed afer use to prevent air from entering, which can cause the adhesive to harden and become less effective. With proper storage and handling, Gorilla Glue can last up to its stated shelf life and provide reliable bonding for a variety of applications.

The Strength of Metal Glue Compared to Welding

Structural adhesives or metal glue can be as strong or even stronger than welding when used appropriately. Welding involves melting and fusing two metal pieces together, while metal glue creates a strong bond by chemically bonding the surfaces of the metal parts.

Structural adhesives are engineered to withstand high stresses and loads, making them an ideal alternative to welding in various applications. The strength of metal glue depends on the type of adhesive used, the preparation of the metal surfaces, and the bonding process.

In some cases, metal glue can even outperform welding. For example, the use of metal glue eliminates the need for metal preparation and finishing operations, which can save time and costs. Additionally, metal glue can bond dissimilar metals, which is difficult to achieve with welding.

However, it’s important to note that the choice between welding and metal glue depends on the specific application and requirements. Welding may still be the preferred option in certain situations, such as when a joint nees to withstand extreme temperatures or pressures. the strength of metal glue and its suitability for a particular application depends on several factors that should be carefully considered before making a decision.

Conclusion

Gorilla Glue is a strong and versatile adhesive that can bond a variety of materials, including metal, plastics, concrete, ceramics, PVC, fiberglass, and more. Whether you need to make a quick repair or tackle a larger project, Gorilla Glue offers a range of products to suit your needs, including their popular GorillaWeld epoxy and Gorilla Super Glue. With its high strength and quick set time, Gorilla Glue is a reliable choice for anyone loking to create a long-lasting, permanent bond. So if you’re looking for an adhesive that can handle even the toughest jobs, look no further than Gorilla Glue.