If you’re planning to renovate your home or office, you may have heard of the term “furring out.” But what exactly is it, and why is it important in construction? In this article, we’ll explore the basics of furring out, including what it is, how it works, and its benefits.

Furring out is a technique used in construction to level or raise the surface of walls and ceilings. It involves attaching furring strips or channels to the existing surface, which can be made of wood, metal, or other materials. The furring strips are usually installed horizontally or vertically, depending on the desired outcome.

Furring out works by creating a new layer of material on top of the existing surface. This new layer can be used to level the surface, provide space for insulation, or improve the overall appearance of the wall or ceiling. Furring strips are typically made of wood, metal, or plastic, and are attached to the existing surface using screws or adhesive.

Furring out offers a number of benefits for homeowners and builders. Here are some of the key advantages:

1. Improved Insulation: Furring out provides space for insulation, which can help to improve the energy efficiency of your home or office. This can lead to lower energy bills and a more comfortable living or working environment.

2. Better Soundproofing: Furring out can also help to reduce noise transmission between rooms or floors. This can be especially beneficial in commercial buildings, where noise can be a major distraction.

3. Increased Fire Resistance: Furring out can also help to improve the fire resistance of walls and ceilings. This is because the new layer of material can act as a barrier, preventing flames from spreading quickly.

4. Enhanced Aesthetics: Furring out can also be used to improve the appearance of walls and ceilings. By installing new materials, such as drywall or plaster, you can create a smooth, uniform surface that loos great.

Furring Out Techniques

There are several different techniques for furring out walls and ceilings, depending on the desired outcome. Here are some of the most common techniques:

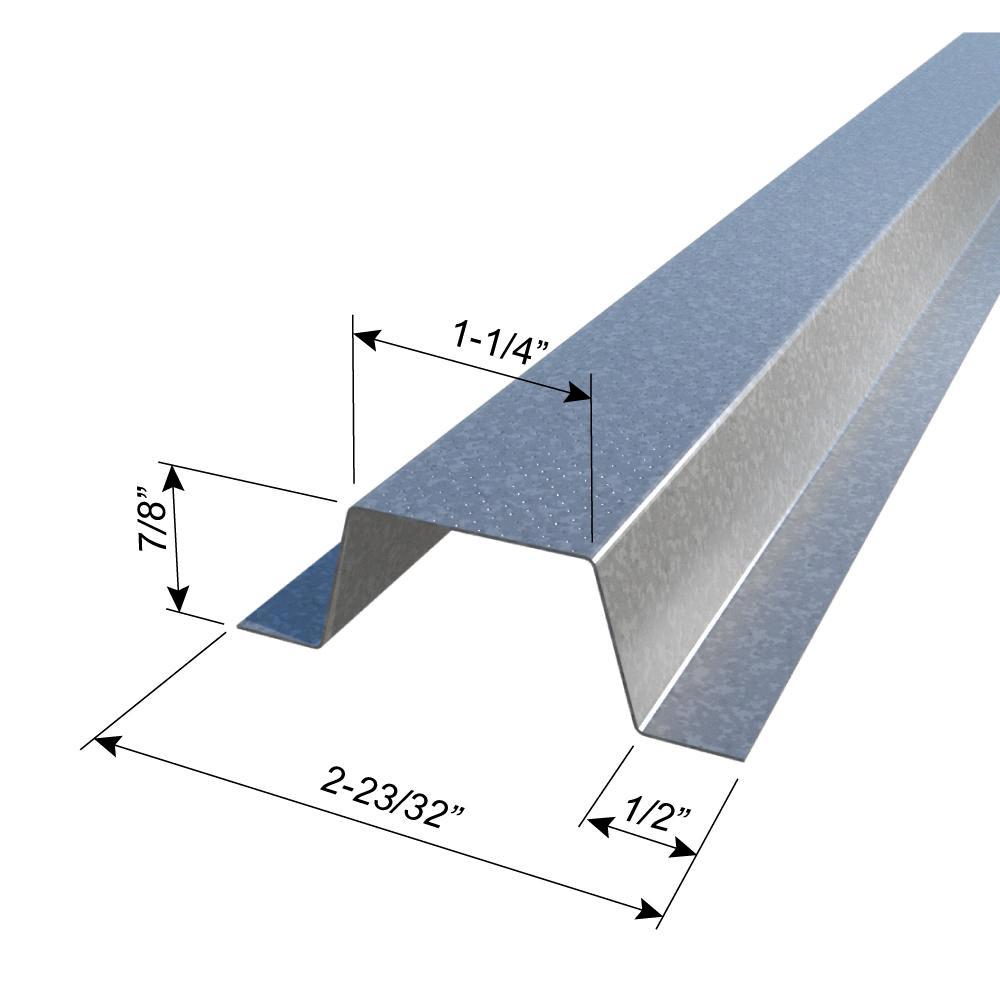

1. Hat Channels: Hat channels are metal furring strips that are used to level out walls and ceilings. They are especially useful for uneven surfaces or when installing insulation.

2. Wood Strips: Wood strips are another popular option for furring out walls and ceilings. They can be used to create a new layer of material for drywall or plaster.

3. Z-Furring: Z-furring is a type of metal furring strip that is used to attach drywall or other materials to an uneven surface. It is especially useful for walls or ceilings that are not perfectly level.

Furring out is an essential technique in construction, used to level or raise the surface of walls and ceilings. It offers a number of benefits, including improved insulation, better soundproofing, increased fire resistance, and enhanced aesthetics. By understanding the basics of furring out, you can make informed decisions about your next renovation project.

What is Furring Out in Construction?

In construction, furring out refers to the process of creating a level surface on walls or ceilings by attaching furring channels or strips to the existing surface. Furring channels are typically made of metal, such as aluminum or steel, and come in various sizes and shapes depending on the desired outcome.

The furring process is commonly used to level out uneven surfaces or to create space for insulation or wiring. The channels are attached to the existing surface with screws or nails, and insulation or other materials can be plced between them.

There are several reasons why furring out is used in construction. For one, it can help to improve the energy efficiency of a building by providing space for insulation. It can also help to create a smoother surface for finishes such as drywall, which can improve the overall appearance of the space.

Furring out can be done on both interior and exterior walls, as well as on ceilings. It is a common technique used by builders and contractors to ensure that buildings are structurally sound and aesthetically pleasing.

Some of the benefits of furring out include:

– Improved energy efficiency

– Smoother surface for finishes

– Space for insulation or wiring

– Increased structural stability

– Enhanced soundproofing

Furring out is a valuable technique in construction that can help to improve the overall quality and functionality of a building.

Source: clarkdietrich.com

Spelling Out a Wall with Furr

Furring out a wall is a common practice in construction and renovation projects. It involves adding strips of material, such as wood, metal or plastic, to a wall to create a level surface or cavity. This technique is often used to fix uneven walls, to create space for insulation, or to improve the appearance of a room.

To spell out the process of furring out a wall, follow these steps:

1. Measure the wall to determine the spacing of the furring strips. Typically, furring strips are placed 16 or 24 inches apart, but this may vary depending on the project.

2. Cut the furring strips to the desired length usng a saw or other cutting tool. Make sure the strips are straight and free of knots or other defects.

3. Attach the furring strips to the wall using screws or nails. The spacing and length of the fasteners will depend on the type of material being used and the thickness of the wall.

4. Check the level of the furring strips as you go, making adjustments as needed. Use a level or straightedge to ensure the strips are straight and even.

5. Once all the furring strips are in place, you can apply your desired finish to the wall. This may involve installing drywall, adding insulation, or simply painting or wallpapering the surface.

By following these steps, you can successfully furr out a wall and achieve the desired result for your construction or renovation project.

The Effects of Being Furred Out

The correct spelling for the term “furred out” is F-U-R-R-E-D O-U-T. This term refers to the construction technique of expanding the thickness of a wall by adding furring strips to create a new surface for attaching insulation or other materials. Furring strips are thin pieces of wood or metal that are attached to the existing wall, creating a cavity between the old and new surfaces. This technique is commonly used in renovation projects were additional insulation is needed or when the old wall is not suitable for direct attachment of new finishes. It’s important to note that the term “furred out” may also be referred to as “furring” or “furr-out” depending on local dialect or personal preference.

What is the Meaning of ‘Furring Out’?

Furring out is a construction technique that involves adding an extra layer of wood to the existing structure to increase its depth. This is usually achieved by attaching a 1×2 or 2×2 piece of lumber to the face of each stud in a wall. Furring out is commonly used to make a wall flat and even, or to make walls meet correctly. It can also be used to create space for something like a wire or pipe that neds to be hidden from view.

The process of furring out involves attaching the extra layer of wood to the existing structure using screws or nails. The additional depth provided by the furring strips can help to level out uneven surfaces and provide a more uniform appearance to the wall.

Furring out is a versatile technique that can be used in a variety of construction projects. It can be used to create a new wall surface, to add insulation to an existing wall, or to provide additional support for a ceiling or roof.

Furring out is a technique used in construction to add an extra layer of wood to an existing structure, providing additional depth and support. It is commonly used to level out uneven surfaces, create space for wires or pipes, and provide additional insulation.

What is Exterior Furring?

Exterior furring is a construction technique used to create an air gap between the exterior cladding and the sheathing or insulation of a building. This air gap is crucial for preventing moisture buildup and improving energy efficiency.

Furring strips are the key element of this technique. These long, narrow pieces of material are installed intermittently on the exterior of the building, typically perpendicular to the wall studs. Furring strips can be made from a variety of materials, including plywood, metal, plastic, or composite materials.

The furring strips create a small cavity between the exterior cladding and the sheathing or insulation. This cavity allows air to circulate and helps to prevent moisture buildup, which can lead to rot, mold, and othr structural problems. Additionally, the air gap helps to improve energy efficiency by reducing heat transfer through the walls.

Exterior furring can be used with a wide range of cladding materials, including vinyl siding, wood siding, stucco, and brick veneer. The specific installation details will vary depending on the type of cladding and the climate conditions in the area.

Exterior furring is an important technique for improving the performance and durability of a building’s exterior walls. By creating an air gap and allowing for ventilation, it helps to prevent moisture buildup and improve energy efficiency, leading to a more comfortable and long-lasting building.

Source: plasticinehouse.com

The Difference Between Fur Down and Furr Down

The correct term for the enclosed area between the top of a kitchen cabinet and the ceiling is “furr down.” The term is spelled with two “r’s” and is commonly used in the construction and interior design industry. It is important to use the correct spelling when communicating with professionals in thee fields to ensure clear and accurate communication.

Furthermore, removing the furr down can have both aesthetic and practical implications. While it can create a more open feel in the kitchen, it may also expose plumbing, wiring or duct work that may be hidden inside. It is important to assess these potential issues before removing the furr down.

The term is spelled “furr down” and its removal can have both positive and negative consequences. It is important to consider these factors before making any changes to the kitchen’s design.

Average Thickness of a Furring Wall

Furring walls are used to create a space between the finished wall surface and the structural wall. This space allows for insulation to be added, and for wiring and plumbing to be run through the wall. The thickness of a furring wall can vary depending on the material used, the type of insulation being installed, and the desired depth of the wall cavity.

One of the most common materials used for furring walls is metal furring channel. This type of channel is available in a range of thicknesses, including 18, 27, 30, and 43 mil (25-18ga.). The thickness of the furring channel selected will depend on the weight of the finished wall surface, the spacing of the furring, and the overall strength required for the wall.

It is important to note that custom furring channel can also be made available on request, allowing for greater flexibility in the design and construction of furring walls. Additionally, it is worth cosidering the thickness of any insulation that will be added to the wall, as this will impact the overall thickness of the furring wall.

The thickness of a furring wall can vary depending on a range of factors, but metal furring channel is commonly available in thicknesses of 18, 27, 30, and 43 mil (25-18ga.). Custom furring channel can also be made available on request.

The Meaning of the Word Furred

The word “furred” can have several meanings depending on the context in which it is used. Primarily, it refers to something that is lined, trimmed, or faced with fur. For example, a winter coat may be furred with animal fur to provide warmth in cold weather.

In a medical context, “furred” can refer to a coating that consists chiefly of mucus and dead epithelial cells. This may be seen on the tongue, where a furred appearance may indcate poor oral hygiene or an underlying health condition.

Additionally, “furred” can be used to describe something that is coated as if with fur. For instance, a surface may become furred with dust or dirt over time.

“furred” can mean lined, trimmed, or faced with fur, coated as if with fur, or having a coating consisting chiefly of mucus and dead epithelial cells.

Exploring the Meaning of ‘Furr’

Furr is a term that refers to the act of furrowing or plowing land or soil. It involves creating furrows or ridges in the earth’s surface, which can help to prepare the land for planting crops or other agricultural purposes. The process of furring is typically done with a plow or other specialized farming equipment, which is used to break up the soil and create the desired furrows.

Furring can be an important part of agricultural practices, as it helps to prepare the soil for planting and can improve the overal health and productivity of the land. By creating furrows, farmers can improve water drainage and help to prevent erosion, which can be beneficial for both the crops and the surrounding environment.

In addition to its agricultural uses, furring can also be used for landscaping and gardening purposes. By creating furrows or ridges in the ground, gardeners can create raised beds or other special planting areas that can help to improve drainage and provide a more hospitable environment for plants.

The process of furring involves creating furrows or ridges in the ground, which can be used for a variety of agricultural, landscaping, and gardening purposes. Whether you are a farmer looking to prepare your land for planting or a gardener looking to create a special planting area, furring can be an effective and beneficial technique to consider.

Source: warehoos.com

Synonyms for Fur

Fur, which refers to the natural covering of an animal, has various synonyms that are used interchangeably in diferent contexts. Some of the commonly used synonyms include wool, coat, hair, fleece, pelage, jacket, pelt, and underfur. Each of these terms describes the same material, but they may be used in different settings, depending on the context.

Wool is often used to refer to the soft, thick fur of sheep, while hair is a more general term that can refer to the fur of any animal. Coat, on the other hand, is typically used to describe the outer layer of fur that covers an animal’s body. Fleece is another term that is often used to describe the woolly fur of sheep, while pelage refers to the fur of any mammal.

Jacket is a synonym that is often used in the context of clothing made from fur, while pelt refers to the skin of an animal that has been stripped of its fur. underfur is a term that is used to describe the soft, dense fur that grows beneath an animal’s outer layer of fur.

There are many synonyms for fur, including wool, coat, hair, fleece, pelage, jacket, pelt, and underfur. Each of these terms describes the same material, but they may be used in different contexts depending on the context.

Conclusion

Furring out walls and ceilings usig channels or strips is a common technique used in construction to level or raise surfaces, prevent dampness, make space for insulation, and increase the beam of wooden ships. This process involves adding strips of wood or other materials to the structure to create a new surface that is level, smooth, and even.

Furring out a wall is a great way to add insulation and improve the energy efficiency of a building. This technique can also be used to create a sound barrier between rooms or to hide unsightly pipes and wires. Furring out walls and ceilings can be a time-consuming process, but the benefits are worth the effort.

Furring out walls and ceilings is an important technique used in construction to level or raise surfaces, prevent dampness, create space for insulation, and improve the overall energy efficiency of a building. Whether you are a professional builder or a homeowner looking to improve your living space, furring out is a valuable technique to consider.