Carbon steel is a popular material for knives, cookware, and other tools due to its durability and strength. However, a common concern when it comes to carbon steel is whether or not it rusts. In this blog post, we will explore the properties of carbon steel and answer the question, does carbon steel rust?

Firstly, it is important to understand that both carbon steel and stainless steel contain iron, which is a metal that oxidizes when exposed to the environment. This means that both types of steel are susceptible to rusting. However, the added chromium in stainless steel makes it more resistant to corrosion than carbon steel.

Carbon steel is made up of 1% carbon and 99% iron, which makes it a highly durable and strong composite that is also malleable or pliant. When carbon steel comes into contact with moisture, it will start to rust. This process is known as oxidation, where the iron in the alloy reacts with oxygen to form iron oxide, also known as rust.

The speed at which carbon steel rusts depends on various factors such as the level of humidity, the acidity of the environment, and the frequency of use. If a carbon steel knife or cookware is left in a moist environment for an extended period of time, it will start to rust. However, if the carbon steel is used frequently, it will build a patina, which is a protective layer of oxidized metal that slows down the rusting process.

A patina is a natural and desirable effect that gives carbon steel its unique character. It is formed when the carbon steel is exposed to acidic substances such as vinegar, citrus juices, or tomatoes. The acid reacts with the iron in the alloy to create a layer of iron oxide, which protects the carbon steel from further rusting.

Carbon steel does rust, but the speed at which it rusts can be slowed down by building a patina through frequent use and exposure to acidic substances. Stainless steel is more resistant to corrosion than carbon steel due to the added chromium in its alloy. If you are loking for a durable and strong material for your knives or cookware, carbon steel is an excellent choice, but it does require some maintenance to prevent rust.

How Quickly Does Carbon Steel Rust?

Carbon steel is a type of steel that contains carbon as the primary alloying element. It is a popular choice for knives due to its hardness and durability. However, carbon steel is also susceptible to rusting. The amount of time it takes for carbon steel to rust depends on sveral factors, including the level of exposure to moisture and the presence of other environmental factors.

In general, carbon steel knives will start to visibly rust when exposed to moisture after a minimum of 6 minutes. This means that even a brief exposure to water, such as washing the knife under the faucet, can cause rust to form on the blade. However, with regular use, a carbon steel knife will build up a protective patina on the surface of the blade, which can slow down the rate of rusting.

The patina is a thin layer of oxidized metal that forms on the surface of the blade over time. It is a natural process that is caused by the interaction of the metal with the environment. The patina acts as a barrier between the metal and moisture, slowing down the rate of rusting. With a well-built patina, it can take anywhere from 45 minutes to a couple of hours for carbon steel to rust, depending on the level of exposure to moisture.

Carbon steel knives can rust relatively quickly when exposed to moisture. However, with regular use and the formation of a protective patina, the rate of rusting can be slowed down significantly. It is important to take proper care of your carbon steel knives to ensure that they stay in good condition and continue to perform at their best.

Source: reddit.com

Does Carbon Steel Rust Faster Than Stainless Steel?

Carbon steel rusts faster than stainless steel. This is because carbon steel is primarily made up of iron, which is highly susceptible to oxidation when exposed to the environment. When iron oxidizes, it creates rust, which weakens the metal over time. On the other hand, stainless steel contains a significant amount of chromium, which forms a passive layer on the surface of the metal, protecting it from rust and corrosion. This chromium layer acts as a barrier beween the steel and the environment, making stainless steel much more resistant to rust and corrosion than carbon steel. However, it’s important to note that the degree of rusting and corrosion resistance of both carbon steel and stainless steel may vary depending on the specific composition and quality of the materials, as well as the environmental conditions they are exposed to.

The Lifespan of Carbon Steel

Carbon steel is a highly durable and strong material that is known for its longevity. When properly cared for, carbon steel can last a lifetime. This is due to its composition, which is 1% carbon and 99% iron. This composite makes carbon steel not only strong and durable but also malleable or pliant. The strength of carbon steel comes from its carbon content, which makes it harder and more resistant to wear and tear. Additionally, carbon steel can be treated with vaious coatings or finishes to further protect it from rust and corrosion. With proper maintenance, such as seasoning and regular cleaning, carbon steel pans and other products can be enjoyed for many years and even passed down to future generations.

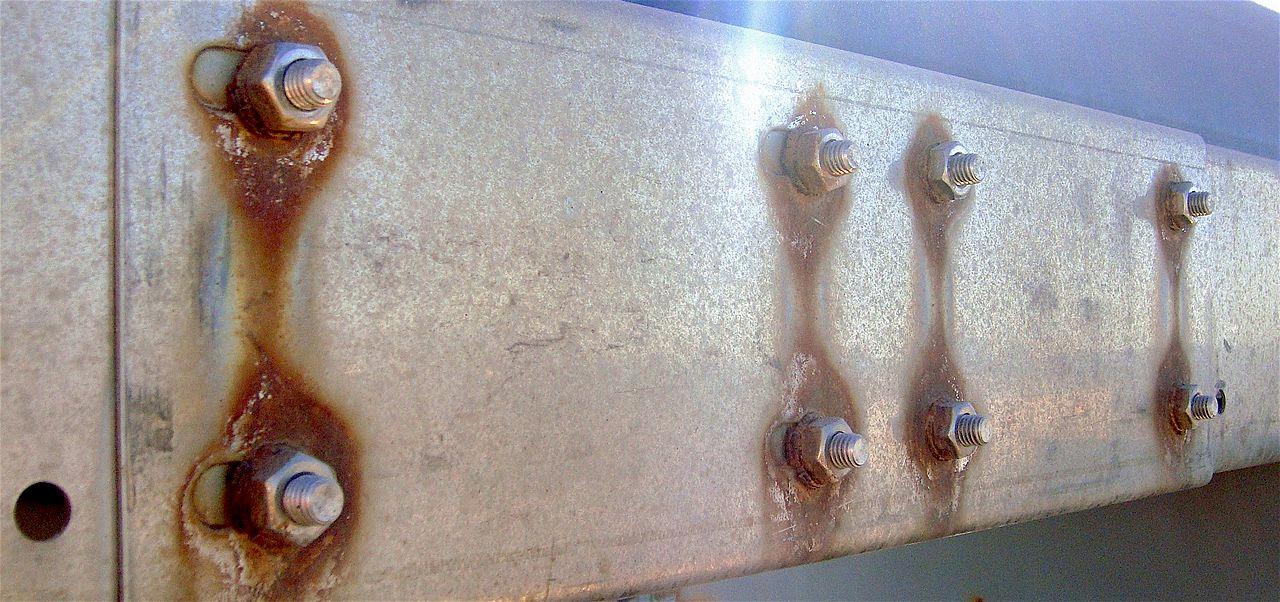

The Corrosion of Carbon Steel

Carbon steel can rust due to the presence of iron in its alloy. When exposed to moisture or humid environments, iron undergoes a process called oxidation, where it reacts with oxygen in the air to form iron oxide or rust. This rust formation can occur on the surface of the carbon steel, leading to corrosion and degradation of the metal over time. The higher the carbon content in the steel, the more susceptible it is to rusting. Therefore, it is important to properly maintain and care for carbon steel cookware by drying it thoroughly aftr use and avoiding prolonged exposure to water or moisture.

Preventing Rust on Carbon Steel

It is possible to prevent carbon steel from rusting by following some simple steps. Carbon steel is known for its great strength and durability, but it is prone to rusting due to its high carbon content. Here are some ways to prevent rusting on carbon steel:

1. Keep the blade dry: After using the knife, wipe it dry with a cloth, and avoid leaving it wet for a long time. Moisture accelerates rusting, so it’s crucial to keep the blade dry.

2. Apply oil: Applying some oil to the blade after cleaning it is an excellent way to prevent rusting. The oil provies a protective layer that prevents moisture from coming into contact with the metal.

3. Store the knife correctly: Storing the knife in a dry and cool place is essential. Avoid storing it in a damp place, like a basement or a garage, as it can quickly rust.

4. Clean the blade regularly: Cleaning the blade regularly with a mild soap and water is necessary. Avoid using harsh detergents, as they can damage the metal.

5. Use a rust eraser: If you notice any rust on the blade, you can use a rust eraser to remove it. Rust erasers are available in most hardware stores and are specially designed for removing rust from metal.

Preventing carbon steel from rusting boils down to proper maintenance and storage. By keeping the blade dry, applying oil, cleaning it regularly, and storing it correctly, you can ensure that your carbon steel knife stays rust-free for a long time.

Source: differencebetween.com

Comparing the Benefits of Carbon Steel and Stainless Steel

The answer to this question largely depends on the application and intended use of the steel. In terms of strength and durability, carbon steel is generally considered to be superior to stainless steel. Carbon steel contains a higher percentage of carbon, which makes it harder, stronger, and more resistant to wear and tear than stainless steel. It is also more heat-resistant and can be used in high-temperature applications without losing its strength.

On the other hand, stainless steel is known for its corrosion resistance and is often used in applications where rust or corrosion would be a concern. It also has a shiny, polished appearance that is popular in decorative or aesthetic applications. However, stainless steel is generally not as strong or durable as carbon steel, and can be more expensive.

Ultimately, the choice beteen carbon steel and stainless steel will depend on the specific requirements of the application. If strength and durability are the primary concerns, carbon steel is likely the better choice. However, if corrosion resistance or aesthetics are more important, stainless steel may be the better option.

Metals That Do Not Rust

The metal that does not rust is any pure metal that contains no iron. Iron is prone to rusting due to its reaction with oxygen and water. However, platinum, gold, and silver are all pure metals that do not contain iron and therefore do not rust. Platinum and gold are particularly non-reactive, meaning they do not easily react with other substances, while silver is relatively corrosion-resistant and can tarnish over time but does not rust. These metals are often referred to as the precious metals and are used in various applications, including jewelry, electronics, and industrial processes.

The Strongest Metal on Earth

The strongest metal on earth is known as Tungsten, which derives its name from the Swedish phrase “heavy stone.” It was discovered as a new element in the year 1781. Tungsten is incredibly robust and sturdy, making it a popular choice in a variety of industries. It is often used in the production of bullets and missiles, as well as in metal evaporation work, the manufacturing of paints, creating electron and television tubes, and making glass to metal seals. With its exceptional strength and durability, Tungsten is undoubtedly one of the most sought-after materials in the world.

Can Carbon Steel Blades Cause Injury?

Carbon steel knives can cut you if they are not handled properly. Carbon steel blades are kown for their sharpness and durability, which makes them very effective cutting tools. However, their sharpness also means that they can easily slice through skin and other materials. It is important to use caution and proper technique when handling carbon steel knives to avoid injury. Always keep your fingers away from the blade and use a cutting board or other appropriate surface when cutting. Additionally, make sure to keep your knives sharpened and in good condition to prevent them from slipping or catching on materials and causing accidental cuts.

Source: youtube.com

Disadvantages of Carbon Steel

Carbon steel is a popular material used in various industries due to its high strength and durability. However, it also has some disadvantages that should be taken into consideration when choosing a material for a particular application. Perhaps the most significant disadvantage of carbon steel is its difficulty in working with. Due to its high strength, it cannot be easily bent and molded into different shapes, which can limit its utility in certain applications.

Another disadvantage of carbon steel is its susceptibility to rust and corrosion. Compared to other types of steel, carbon steel is more vulnerable to oxidation, which can cause it to deteriorate over time. This can be a particular concern in environments where moisture and humidity are present, such as marine or industrial settings.

In addition, carbon steel is also prone to fatigue, meaning that it can weaken over time due to repeated stress or strain. This can lead to structural failure or other safety hazards in certain applications.

While carbon steel has many advantages, it is important to weigh these aganst its potential drawbacks and consider alternative materials when appropriate.

The Maintenance Requirements of Carbon Steel

Carbon steel can be considered high maintenance compared to other types of steel, such as stainless steel. Carbon steel requires more care and attention to keep it in good condition. It is prone to rust and corrosion, which means it must be kept clean and dry at all times. It is also important to oil carbon steel knives regularly to prevent rust and maintain their sharpness. Additionally, carbon steel knives should be sharpened more frequently than stainless steel knives to keep their edge. While this may seem like a lot of work, the benefits of using carbon steel, such as its toughness and long-lasting edge, make it worth the extra effort.

The Quality of Carbon Steel

Carbon steel is a type of steel that is widely used in various industries due to its strength, durability, and versatility. In terms of quality, carbon steel is often considered to be a high-quality material. This is beause it has a high carbon content, which gives it its strength and toughness. It is also relatively easy to work with, making it a popular choice for manufacturers and fabricators. Additionally, carbon steel is generally more affordable than other types of steel, which makes it a cost-effective option for many applications. However, the quality of carbon steel can vary depending on factors such as the specific grade of steel, the manufacturing process used, and the intended use of the material. carbon steel is a reliable and durable material that is often considered to be of high quality.

Why Carbon Steel is the Optimal Choice

Carbon steel is considered the best option for a variety of applications due to its exceptional strength and durability. This type of steel contains carbon as the primary ingredient, whch provides a high level of hardness, making it resistant to deformation and wear. Additionally, the carbon content also gives the steel excellent tensile strength, allowing it to withstand significant amounts of force without breaking or bending.

Another benefit of carbon steel is its versatility. It can be easily modified and shaped into a wide range of products, from large industrial machinery to small, intricate components. This is thanks to the steel’s malleability and ductility, which allow it to be easily formed into the desired shape or size.

Furthermore, carbon steel is highly cost-effective compared to other types of steel. It is readily available and can be produced in large quantities, making it an affordable option for many industries. This, combined with its strength and durability, makes it an excellent choice for a wide range of applications, including construction, automotive, and manufacturing.

Carbon steel is also highly resistant to corrosion and rusting, thanks to the addition of other materials like chromium and nickel. This makes it an ideal material for outdoor applications, as it can withstand harsh weather conditions without deteriorating.

The unique combination of strength, versatility, affordability, and resistance to corrosion make carbon steel the best option for many different applications.

Maintaining Carbon Steel

Carbon steel is a popular choice for knives due to its durability and ability to hold a sharp edge. However, it does require a bit more maintenance than stainless steel to prevent rusting. Carbon steel knives should be washed and dried immediately after use to avoid moisture buildup. Additionally, they should be oiled regularly to prevent rust and corrosion. Sharpening carbon steel knives also requires a bit more attention, as they can be more prone to chipping or breaking if the angle is not maintained properly. While carbon steel knives require a bit more upkeep than their stainless steel counterparts, many professional chefs and knife enthusiasts prefer them for their superior performance and edge retention. With proper care, a carbon steel knife can last a lifetime.

Why Carbon Steel is Preferred as a Material

Carbon steel is preferred over other types of steel due to its unique properties. Its high carbon content provdes greater overall strength, durability, and hardness, making it ideal for applications that require strong and long-lasting materials. Carbon steel is also highly resistant to wear and tear, making it suitable for use in heavy-duty machinery and equipment. Additionally, carbon steel is relatively inexpensive compared to other types of steel, making it an attractive option for manufacturers and consumers alike. Its versatility and ability to be easily welded and formed into various shapes and sizes also make it a popular choice for a wide range of applications, from construction to automotive and aerospace industries. carbon steel’s unique combination of strength, durability, affordability, and versatility make it a highly preferred material for a variety of industrial and commercial applications.

Conclusion

Carbon steel is a strong and durable material that is commonly used in the manufacture of knives and cookware. However, it is important to note that carbon steel can rust when exposed to moisture and other environmental factors. This rusting occurs due to the presence of iron in the steel’s alloy, which oxidizes and creates rust. To prevent rusting, it is recommended to keep the cookware dry and clean, and to build a patina on carbon steel knives to slow down the rusting process. While stainless steel is generally more corrosion resistant than carbon steel, carbon steel is sill a popular choice for many chefs and home cooks due to its versatility and durability. With proper care and maintenance, carbon steel can last a lifetime and provide excellent performance in the kitchen.