Cripple studs are short pieces of lumber used in framing for a variety of purposes. They are installed above headers, below window sills, and in other areas where additional framing is needed. Cripple studs can also be used to support the weight of headers and to provide a nailing base for siding or interior wall coverings.

Cripple studs can be found in many different sizes, depending on the application. For example, shorter pieces are used for headers while longer ones are used for windows and doors. They can also be cut to fit between posts, such as those found in crawl spaces.

The most important thing to remember when using cripple studs is that they are non-structural – meaning they do not carry any load-bearing weight but instead offer support through nailing or bolting them into place. This shuld be done carefully and properly to ensure the stability and integrity of your structure.

When installing cripple studs, it’s important to measure the area where they will be placed before cutting them down. This will help you determine the correct size based on your project’s needs and specifications. You should also use appropriate hardware such as nails or bolts when attaching them to ensure a secure fit. Additionally, if you’re replacing old cripple studs with new ones, make sure to remove all old materials from the area before installing the new ones so that there is nothing preventing them from fitting properly into place.

In conclusion, cripple studs are an important part of any framing project as they provide extra support where needed and can help ensure a strong structure over time. Be sure to take proper measurements before cutting your cripple studs down and always use appropriate hardware when attaching them into place for optimal results.

Understanding the Purpose of a Cripple Stud in Framing

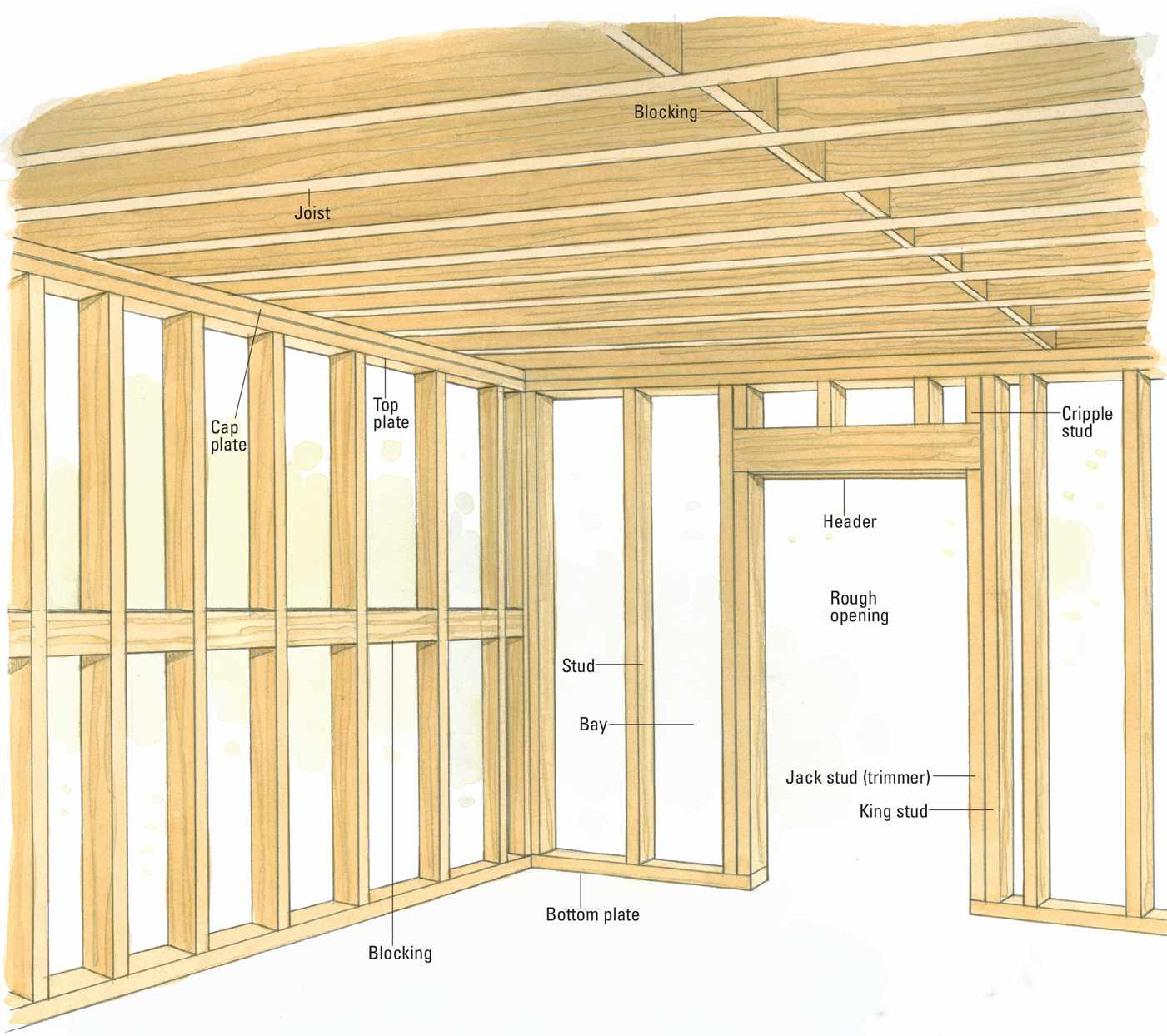

A cripple stud is a short stud that is installed above a header or below a window sill or saddle in framing. It is typically used to provide additional support for the header or window opening, as well as to help maintain the structural integrity of the frame. Cripple studs are usually made from two-by-four lumber and are fastened to the wall frame with nails or screws. They may also be used to attach drywall, siding, and oher materials to the wall frame. Properly installed cripple studs can help prevent buckling of walls and other problems associated with poor framing techniques.

Comparing a Cripple Stud to a Jack Stud

No, a cripple stud is not the same as a jack stud. A jack stud is used to support the weight of the header and is typically installed in pairs on either side of the window or door opening. A cripple stud, on the other hand, is cut to add additional framing above the door or window opening and below a window. Cripple studs are often used to help support heavier load-bearing walls or when more stability and strength are needed in an area.

Uses of a Cripple Stud

A cripple stud is a short piece of timber that is installed above or below a door, window, or other opening to provide support for the siding or interior wall covering. It is not structural in nature but serves as a nailing base to secure the siding or wall covering in place. In addition, a cripple rafter may be used on roofs to bridge between hip and valley rafters and to cut short to accommodate an opening such as a chimney or skylight.

Understanding the Origin of the Term ‘Cripple Stud’

A cripple stud is so named because it is shorter than other studs, often providing support for headers and plates. Its length makes it less useful for load-bearing purposes, unlike full-length studs, which can be used to provide support for walls and ceilings. In this sense, the cripple stud is “crippled” or limited in its application. The term can also refer to a series of short studs that are installed around a crawl space to provide extra support for the walls and ceiling, since these spaces typically have limited headroom.

Types of Studs

There are four distinct types of studs available, each with their own unique properties.

Class 1 studs have an interference fit at one end and a free-running thread at the other. This type is typically used in applications that require greater strength, such as in structural steel framing or aircraft construction.

Class 2 studs have free-running threads at both ends, making them ideal for attaching components which will require frequent disassembly.

Class 3 studs are three-bolt studs designed for high temperature/pressure applications, such as in boilers and steam engines.

Finally, Class 4 studs are designed for general purpose applications. These have a wide range of uses, including automotive and plumbing applications.

The Origin of the Term ‘Cripple Wall’

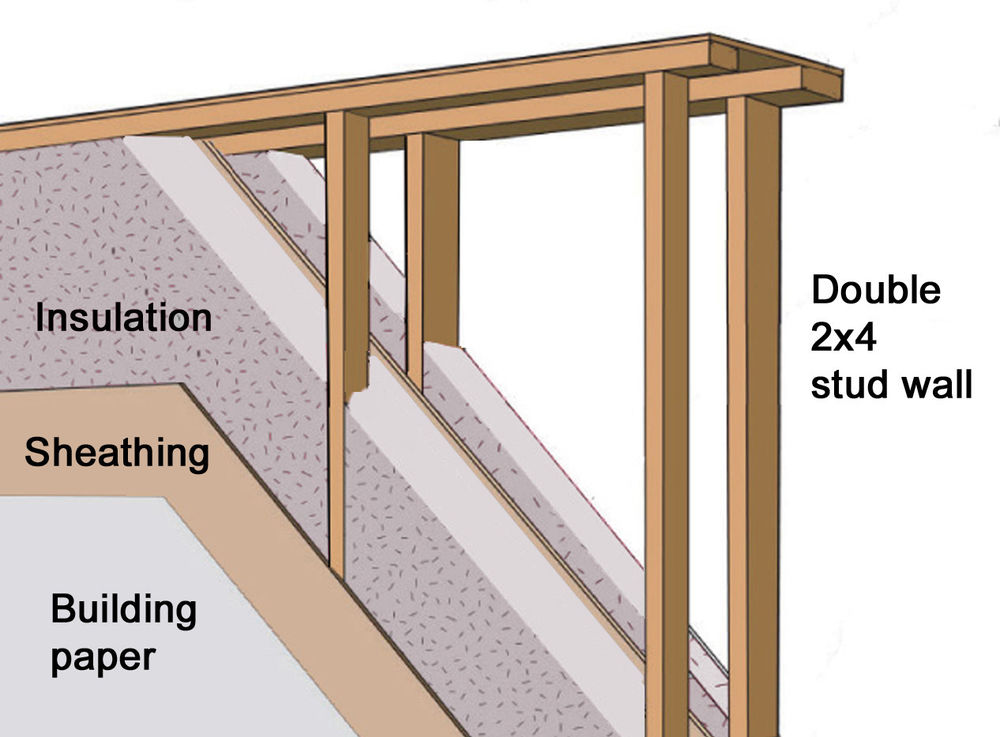

A cripple wall is a section of the home that is specifically designed to absorb the energy of an earthquake, helping to protect the rest of the house from serious damage. This area of the home is known as a “cripple zone” becaue it is designed to “cripple” or give way in order to reduce the seismic force on the rest of the house. The use of this type of wall has been shown to be beneficial in reducing earthquake damage by providing a weak point for seismic forces to disperse before reaching other parts of the building, thus protecting it from more serious structural damage.

Difference Between Trimmer and Cripple Stud

A trimmer and cripple stud may look similar, but they serve distinct purposes in a building. A trimmer is a full-length stud that runs parallel to the primary floor or ceiling joists and supports headers, which run perpendicular to the primary joists. A cripple is a shorter stud that acts as a support for headers above window or door openings. The length of a cripple varies depending on the size of the opening, while trimmers are usually cut to standard lengths.

Installing Cripple Studs

Cripple studs are short pieces of lumber used to fill the space between the bottom plate and sill of a window or door opening. The cripple studs should be placed so that their top edge is level with the bottom edge of the window or door opening, and they should be spaced at regular intervals to match the spacing of the other common studs in the wall. In most cases, this means that cripple studs should be installed 16-24 inches apart on center, depending on what spacing has been used for the other common studs. The cripple studs should also be securely fastened to both the sill and bottom plate using appopriate nails or screws.

Length of a Cripple Stud

Cripple studs should be no less than 14 inches (356 mm) in length. If the cripple wall is more than 4 feet (1219 mm) in height, then the studs should have the size required for an additional story, as stated in Section 2308.6 of building codes.

The Appearance of Cripple Walls

Cripple walls are a type of structural support found in many residential homes. They are typically made of wood framing, which consists of 2x4s or 2x6s that are placed between the foundation and the first floor. Cripple walls generally run the entire length of a house, from corner to corner, and can be anywhere from 18 inches to 3 feet tall depending on the design of the home. They usually have an opening at one end for access to a crawl space uderneath the house, which can be used for mechanical systems or storage. On the exterior of the home, cripple walls may be covered with siding or left exposed, depending on personal preference.

The Purpose of Purple Studs

Purple studs are a type of wooden framing component primarily used in residential construction projects. They are typically made from Southern yellow pine and feature a vibrant purple color that sets them apart from other kinds of studs. Purple studs can be used for load-bearing walls, interior and exterior walls, as well as floor and roof supports. Their size and strength makes them suitable for a variety of uses, such as window frames, door frames, staircases, decks, porches and more. The vibrant purple color also makes them visually appealing and helps to differentiate the product in the marketplace.

Calculating the Number of Cripple Studs Needed for a Door Frame

Cripple studs are used to provide extra support for door frames. You will need two cripple studs for each side of the door frame opening. The first one should be placed directly above the top plate and the second should be placed directly below the bottom plate. The length of each cripple stud should be equal to the height of your door plus 2-1/2 inches, minus 1-1/2 inches to accommodate for the thickness of the bottom plate. If you are installing a prehung door, you may need additional cripple studs depending on how it is framed.

What is the Meaning of Crowning Studs?

Crowning studs is the process of using a level or straight edge to check for curves in a piece of lumber. It’s an important step in any woodworking project, as it ensures that the lumber is straight and true. This helps to ensure that the finished product will be strong and properly aligned. To crown a stud, you first need to make sure that the board is fully supported on both sides and is resting flat on a surface. Then you take your straight edge or level and run it along one side of the wood, from end to end. If there are any dips or bulges in the wood, then it needs to be corrected before beig used in your project. Crowning studs is an important part of making sure that your project turns out just right!

Understanding the Purpose of a Jack Stud

A jack stud is a structural element that supports a header, transferring its load dwnward to the bottom plate and foundation. It is usually made from wood, but may also be constructed from steel or other materials. Its length determines the height of the header, and is important for creating rough openings for windows and doors. The jack stud is typically placed below the header and attached to it with nails or screws. It also provides support for drywall, siding and other finishes around windows and doors. Properly installed, a jack stud can help prevent bowing or warping of door frames and window frames due to pressure from above.

Identifying a Hidden Device Known as a Stud

A stud is a vertical structural component of a structure, such as a wall, ceiling, or floor. It is typically made of wood and is used to support other components within the structure. A hidden device called a stud finder, also known as a stud detector or stud sensor, is used to locate the position of these hidden studs. This handheld tool works by sending an electronic signal through the wall surface and measuring the electrical resistance that it encounters. The change in electrical resistance indicates the presence of a stud behind the wall surface.

Conclusion

In conclusion, cripple studs are an important part of the framing process in building. They are cut to fit between a header and top plate or between a sole plate and rough sill for a window. Generally, cripple studs are non-structural but provide a nailing base for siding or interior wall coverings. Cripple studs are also used in the cripple walls around a crawl space. With their versatile uses, cripple studs can be seen as essential in making sure that any building project is built properly and safely.