Chamfered edges are a great way to add a touch of style and sophistication to any project. Whether you’re creating a new piece of furniture, building a new structure, or even just adding a decorative touch to an existing item, chamfered edges can make all the difference. But what exactly is chamfering and why should you consider it for your next project?

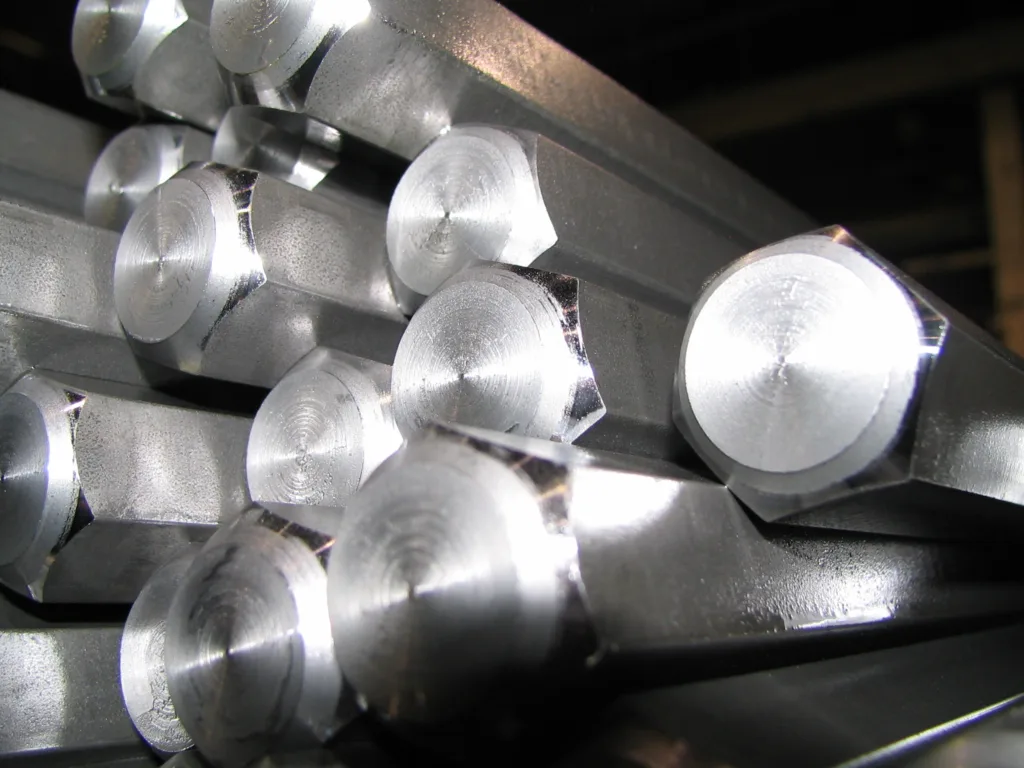

Chamfering is the process of cutting away or beveling the sharp edges of materials such as wood, metal, concrete, and more. It’s done by cutting away at an angle so that the two surfaces meet at a 45-degree angle instead of a 90-degree angle. This creates an attractive finished look with clean lines and rounded corners.

Chamfering also serves an important functional purpose in addition to its aesthetic benefits. By beveling the edges, you reduce the risk of chipping or other damage that can occur when working with materials like concrete or metal. This is especially beneficial in construction projects whee any damage can be costly and time consuming to repair.

In addition to preventing damage from occurring during construction projects, chamfering can also be used to mask imperfections or damage on existing materials such as furniture or walls. By cutting away at an angle, you can effectively hide any existing flaws without having to replace the entire material.

Finally, chamfering can also help minimize potential damage to other objects that might come into contact with your project. By eliminating sharp edges and corners, you reduce the risk of causing injury or damaging other items in contact with yours.

Overall, chamfering is an effective way to both improve the look of your project and ensure its longevity by reducing potential damage from occurring over time. Whether you’re building something from scratch or simply refinishing an existing item, adding a few beveled edges is sure to give it that perfect finishing touch!

Creating Chamfered Edges

To make chamfered edges, you’ll need to use a 3D modeling software such as Blender or 3ds Max. First, go to Tools > Chamfer/Fillet. Select the type of chamfer you’d like to create. Then, select the edges that you want to chamfer. If you’re in “Auto” mode, pull the edges inwards and adjust them to create a smooth blend. You can also select the dimension label to define exact values of the chamfer size. Once you’re happy with your design, select Done to finish creating your chamfered edges.

Difference Between Bevel and Chamfer

The main difference between a bevel and a chamfer is the angle at which the two surfaces meet. A bevel has an edge that is sloped at any angle except 90 or 45 degrees, while a chamfer has an edge that meets two surfaces at a 45-degree angle. Bevels can be used to create angled edges and corners, while chamfers are typically used to smooth edges and remove sharp points. Additionally, chamfers are generally easier to create than bevels as they require less precise cutting of the materials being worked on.

Understanding the Meaning of Chamfering

Chamfering is a technique used to create an angled edge on a material, typically by removing a portion of the corner or edge. This angled edge is referred to as a chamfer and it can be used for various purposes, such as improving the look of a material, preventing sharp edges from catching, or making it easier for two pieces of material to fit together. Chamfering tools are used to achieve this and often come in the form of a router bit, grinding wheel, or file.

Benefits of Chamfering Concrete Edges

Chamfering concrete edges is an important step in the construction process, as it helps to reduce potential damage and increase the overall structural integrity of the concrete. By softening sharp corners, chamfering can prevent chipping and other damage caused by impact or abrasion. Additionally, it can help to mask any imperfections or structural damage on previously cured concrete. Finally, chamfering also helps to minimize potential damage to other objects that may come into contact with the concrete edges.

Is a Chamfer Always 45 Degrees?

Yes, a chamfer is always 45 degrees. A chamfer is a type of transition between two right-angled surfaces of the same part, and it is used to create smoother edges than the 90-degree angle of the part would otherwise have. By angling one surface at 45 degrees relative to the other, it creates a smoother edge that can reduce risk of injuries during handling.

Source: popularwoodworking.com

What Is the Alternative Name for Chamfer?

A chamfer is a type of beveled edge, so another name for it would be a bevel. A bevel is an angled cut that forms an edge between two surfaces, usually at 45 degrees. To create a chamfer, the surface is cut away at an angle to create a sloping edge. Other words for this include slope, oblique, cant, diagonal, bezel, tilt, mitre (UK) or miter (US).

The Purpose of a Chamfer

The function of a chamfer is to soften the edges of furniture such as counters and table tops. By beveling or chamfering the edges, it helps to prevent bruising when bumped against or otherwise contacted with the sharp corner. This technique also creates a more aesthetically pleasing look as opposed to leaving the corner sharp and angular.

What is a Rounded Chamfer?

A rounded chamfer is a type of edge treatment known as a radiused chamfer. This entails the chamfer being rounded off to create a smoother transition from one surface to another. This is often used when edges must remain sharp but still need to be softened or blended into the adjacent surfaces. Radiused chamfers can be created with a variety of tools, including machining, grinding, filing and sanding.

What is the Meaning of Chamfered End?

A chamfered end is a type of edge or corner cut that has been beveled slightly to create an angled edge. This type of cut is often used to give a more finished look to the edge, as well as provide strength and stability. It can be used on many different materials such as wood, metal, and plastic. The angled edge has the advantage of being less prone to catching on other surfaces, making it ideal for applications where a smooth transition between two surfaces is desired.

What is a Bevel Edge?

A bevel edge is an angled edge, usually at 45 degrees, on a piece of material. It is created by cutting or grinding the surface of the material at an angle so that it is not a straight line. Bevel edges are used to add decorative elements to pieces, as well as for safety purposes; for example, a beveled edge on the corner of a countertop can prevent people from tripping and injuring themselves. Beveled edges are also used in engineering and construction projects for structural strength and for aesthetic reasons.

Using Chamfer Edge

To chamfer the edges, you will need to switch on the edge router near to the workpiece. Then, guide the tool flush along the edge and route the required profile in a slow and even motion, going in the opposite direction. Make sure that you go all the way along the edge up to the end of the workpiece and then switch off the tool when you have finished routing. This will help to prevent any burn marks.

Difference Between Chamfer and Taper

A chamfer is an angled cut on the edge or corner of a material, usually at 45 degrees. It is used for a variety of purposes, such as removing sharp edges, creating a decorative effect, and improving the fit of two pieces when joined. The angle is typically shallow and the width is usually uniform.

A taper is similar to a chamfer but it extends further aong the edge or corner of the material. The angle may be more steep than a chamfer and can range from shallow to sharp. The taper may also be variable in width, meaning it starts off wide and gradually gets narrower until it reaches its point at the end. This type of taper is commonly used in carpentry and joinery applications to create joints that are stronger and less prone to splitting.

Common Angle of a Chamfer

The common angle of a chamfer is typically between 20 and 45 degrees. This angle is the lead angle in which the cutting tool enters the workpiece. The width of the chamfer, or the distance from the entrance point to the surface of the part, is usually kept below 30% of the feed. In terms of specific measurements, this is equal to a range of 0.1 to 2.0 mm.

Conclusion

In conclusion, chamfered edges are a great way to protect against damage and mask imperfections in both green and cured concrete. The 45-degree angle of the chamfer helps prevent chipping, as well as eliminates sharp corners that could cause further damage. They also help to minimize potential damage to other objects, making them a valuable tool in concrete projects large and small.